Smooth Operator: Mastering the Asphalt Roller

An asphalt roller is one of the most essential equipments that comes into the picture during the construction and the repairing of roadways, parking lots or any kind of surfaces which require to be made durable and smooth.

These machines basically are made for the purpose of compacting asphalt mixtures, in the process of which they should be able to meet the required density and stability which subsequently would result in a long-lasting performance.

Asphalt rollers are available in different varieties such as static, vibratory, and pneumatic-tired rollers, of which each has different functions depending on the project requirements.

In other words, static rollers use their heaviness to compress the asphalt, while vibratory ones implement a mixture of weight and vibration to accomplish compaction in a more efficient way. Pneumatic-tired rollers simply take the help of air-filled tires for the kneading motion which is the source of an easy and even surface to come out.

An asphalt roller operation is an art that the performer has to constantly analyze the course material as well as the conditions prevailing in the environment.

The asphalt mix temperature is the deciding factor; for best compaction it should be at a specific point. If before rolling the asphalt is getting too cold then insufficient compaction can be the result of it which in turn will simply produce a surface that is likely to crack under any other forms of distress.

In addition, the driver should find out not only the optimum speed for the roller but also the number of passes that need to be done in order to reach the required density. Sometimes, each project may be full of challenges, so we may need to adapt rolling methods and choose different tools to overcome them.

Key Takeaways

- The asphalt roller is a piece of heavy equipment that is used to compact the asphalt and the result should be a surface that is both smooth and even.

- The safety steps that need to be taken when working with an asphalt roller, include being properly dressed in protective gear and making sure the area is free from any dangerous objects that might cause you to trip while you are working.

- The caring and checking of the asphalt roller by the user is a must to regulations its best performance and thus the longest life it can give.

- The main ways to get the asphalt roller to give a good finish, are to make several passes and to use the right amount of compaction force.

- While operating the asphalt roller, the operators should be very careful and try their best to not do over-compaction and to avoid improper rolling patterns.

Safety Precautions for Operating an Asphalt Roller

Asphalt Roller operation is a risky business thus, strict safety measuring is an absolute must in the case of human error either for the operator or the people who are in the vicinity.

Firstly, all safety measures recommended are: the training of operators, ensuring they are acquainted with the roller’s brand and model and the general overview of instructions not only by operation but also in the emergency regime in the event of a breakdown of the equipment or accidents.

Appropriate personal protective equipment (PPE) such as hard hats, high-visibility vests, gloves, and steel-toed boots to cover the head, making it easy to spot the worker on the site, protect the hands and the feet from possible injuries, are essential for every worker to use during work.

A critical step to safety on the team is establishing a signaling system among the workers. The operator of the heavy machinery is not the only one that can see the spotter can also be employed to help guide the operator, especially in tight spaces or when working near pedestrians or other vehicles safely which is another important way to keep them from any accidents.

Also, the workers need to do the checking their rollers have troubles, so a mechanical issue or accident-causing will never happen. Checking the lubricant level, brakes, lights, and taking care of other small but essential parts for machine safety should be done before every use.

Proper Maintenance and Inspection of the Asphalt Roller

Maintenance on a regular basis and the inspection of an asphalt roller are paramount to its durability and functionality at the highest level. Apart from that, a roller which has been well maintained will not only function at a higher level, but will also minimize the chances of interruption during the work that may result in expensive downtime besides it will save time too.

To achieve these results a daily check before the machine is operated and even more detailed checks at the intervals suggested by the manufacturer should be a part of the routine maintenance schedule of the operators.

The main part of daily checks should involve checking of all the fluid levels – such as the hydraulic oil, the fuel, the water as well as the tire pressure for pneumatic rollers and the general cleanliness of the machine should be carried out.

Apart from daily inspections the operators should also be involved in routine maintenance activities such as the replacement of hydraulic filters, the inspection of belts and hoses for wear, and the greasing of the moving parts.

The cleaner the roller, the better it is for the machine; the packed asphalt can gradually cause corrosion as well as other mechanical issues. On top of this, when using the machine operators should check for disturbing sounds and vibrations which can be the earliest signs of mechanical problems and thus require prompt action.

By sticking to the maintenance and the inspection program, the operators will be assured that their tools will be in the best shape when needed at the construction sites.

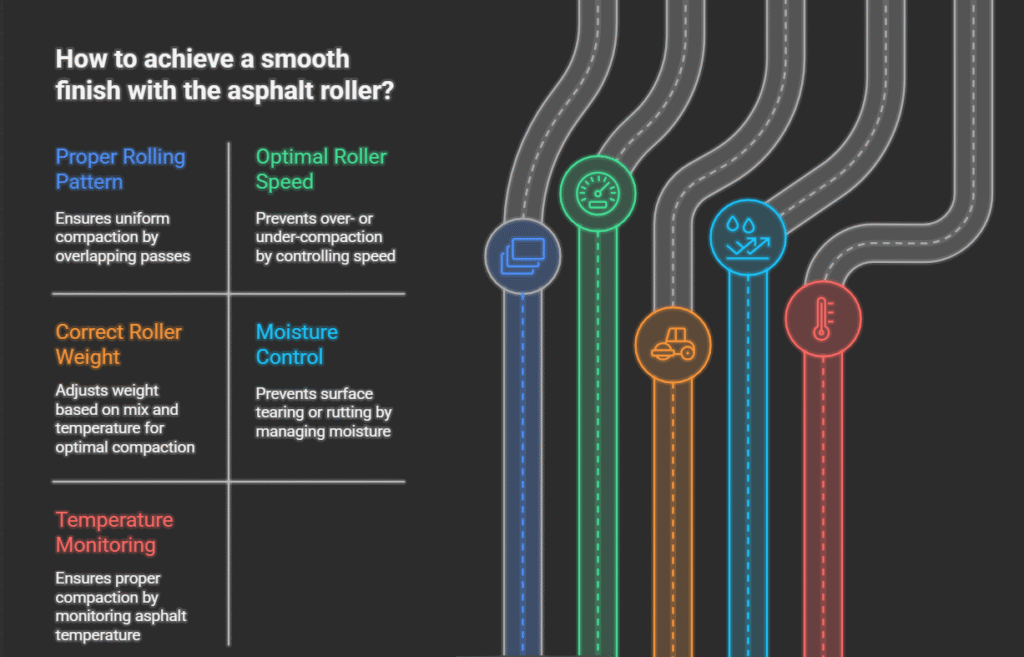

Techniques for Achieving a Smooth Finish with the Asphalt Roller

In order to get a smooth finish while using an asphalt roller, the operator should know what kind of material he is dealing with, as well as the correct method.

One of the methods could be the starting point of rolling at the edges of the asphalted zone and moving towards the center. The process allows one to get rid of the possibility of the formation of ridget or unevenness on the side, which may be caused if the roller is placed in the middle and the work goes on from there.

Proper overlapping of the passes by about one-third can also lead to even compaction throughout the surface, and this can be one of the considerations for the operators.

Speed of the asphalt roller is also a very determining factor of the smoothness of the finish. In general, a slow pace will allow better compaction, especially if the asphalt is in a thick layer.

Nonetheless, the operators have to use the speed to their advantage; if they drive too slow, the asphalt mix will cool off too much, and if they go too fast, the compaction will be insufficient. Also, the setting of the vibration of the vibratory roller can be changed in such a way that the effect of the compaction is maximized but surface smoothness is not compromised.

As a result of hard work in achieving these goals, operators will experience not only the quality of work improvement but also the prolonging of the lifespan of paved surfaces.

Common Mistakes to Avoid When Operating an Asphalt Roller

Even operators who are skilled can make the same mistakes that are typical when using an asphalt roller and, as a result, they might affect the quality of their work.

One of the common errors that take place is the lack of closely monitoring the temperature of the asphalt mix. We have already said that if the asphalt is too cold, it is difficult to make the necessary compaction. Those who are in charge of operations have to always adhere to the temperature guidelines given by the suppliers of the materials and change their rolling time accordingly.

It is also a big mistake not to consider environmental factors such as relative humidity and the velocity of the wind, which can influence the cooling rate of the asphalt.

It is like being at the place where the wind blows very hard and rolling is going on. The asphalt could be cooling at a faster rate that you had previously thought; hence you would have to make a change in rolling methodology or time.

Some workers could be less than perfectly aware of the necessity of the regularity of the pressure on the pneumatic-tired rollers; in both cases, even the tire pressure can cause different compactions on the surface of different patches, which in turn could lead to the surface becoming uneven. By being aware of such common errors, the staff members can boost their work performance and get better results.

Environmental Considerations When Using an Asphalt Roller

One of the main issues leading to the problem of air pollution is the rolling machine on diesel power. The rolling machines on diesel powers release emission gases, which not only pollute the air we breathe but can also lead to health problems for workers and the community living in the vicinity.

As a solution to this issue, some manufacturers are now propelling the effort to produce green models with alternative fuel or hybrid technology which would then be a double benefit: less emission of polluting gases and more fuel efficiency. Their revolutionary inventions are not only great at cutting off emissions but also managing the fuel cavity to make them the most economical over a long period of time.

Furthermore, operators need to be mindful of the pollution by noise accompanying the approach of the asphalt rolling machines. Noise the matter can become an enemy of those living near facets, and also the fauna; the animals can be disturbed, and as a result, there could be complaints or tighter supervision from the authorities.

The solution to this problem is some companies investing in less noisy machines or using methods that lessen the noise, such as working during the quietest hours or using barricades around the work zone to block the sound.

Moreover, the waste generated from asphalt industries should be properly managed if the goal is to reduce their negative impact on the environment and also encourage sustainability in the construction sector.

Advanced Tips for Mastering the Art of Asphalt Rolling

One of the best ways to get better at handling an asphalt roller is to use the tips described below by the professionals who have gone through a similar experience.

The main idea is to develop the sense of timing while performing a rolling operation. On the whole, one should understand the right moment for rolling after the asphalt has been laid. Applying too little force will achieve insufficient compaction, while the asphalt will cool off if one pulls away too late.

Skilled operators frequently base this timing on intuition derived from such instances as air temperature and moisture in the air. Besides, different roller setups can be utilized for different projects is another trick.

As an example, having a double roller of both vibratory and pneumatic tired working simultaneously on a certain surface may cause the unexpected good results because we are using the advantages of both types.

Moreover, the operator should also try out various patterns such as circular or figure-eight rolling motions to explore which one could suit certain materials in a specific project.

Continuos learning by participating in workshops or attending training sessions adds up to the positive experience by exposing new ideas of the technologies and techniques of asphalt rolling.

The Future of Asphalt Rolling: Innovations and Trends

The fundamental elements of the advanced future for asphalt rolling come from disruptive digital innovations and progressive standards in the asphalt industry.

One of the most noticeable trends that are already coming to the fore is the use of automatic, high-precision technology in construction machinery, asphalt rollers included.

Precision in compaction can be brought to a higher level with the help of automated equipment where different sensors playing the role of temperature and density indicators give their reading and as a result, adjustments can be made in real-time for the best outcome.

Also, major developments in the field of materials science are the roots for the birth of asphalt mixtures that are more environmentally friendly and that also use more recycled raw materials or binders with lower carbon emissions.

As these materials become more commonplace in construction, asphalt rollers will have to be modified so that compacting can be done well and the quality standards will not be challenged.

Next to that, data analytics is also taking a prominent position in construction management; operators may soon be using data-driven insights from the past projects to plan the current ones and make them move faster.

As the future of these trends continues to take shape, it will be very clear to the operators who want to have the advantage that the best strategy in this area is to keep pace with technology-driven changes and also upgrade one’s knowledge of new materials.

Consequently, the commitments to safety and environmental solidarity have become not only the impacts on asphalt rolling machine operation but also the driving forces that lead toward the construction of sustainable infrastructure within the world’s communities.