Skid Steer Loaders: The Ultimate Guide to Versatility on Wheels

Introduction to Skid Steer Loaders

What is a skid steer loader?

A skid steer loader is a small, engine-powered machine with lift arms that are compatible with a vast range of tools and attachments. It is one of the most versatile pieces of equipment on any job site. The skid steer can do all sorts of work, like digging, grading, lifting, or clearing, and that too in a very short time and efficient manner.

As the name “Skid Steer” indicates, the machine has a different way of steering. A skid steer turns by skidding its wheels—left wheels moving separately from the right—whereas traditional wheeled vehicles turn with a steering wheel. This allows for making very small, zero-radius turns which are great for operation in narrow spaces.

The list of applications for skid steers is practically endless. They are found in construction, landscaping, agriculture, snow removal, and roadwork, among others. In fact, they are sometimes referred to as the “Swiss Army knife” of heavy equipment, not only because of their ability to change attachments rapidly but also due to their versatility.

Mini loaders in small sizes to large-frame models that can lift more than 3,000 pounds are available, so you can find a skid steer for almost any work. Skid steers are the most important machines for the productivity of contractors, landscapers, and farm operators.

Evolution and History of Skid Steers

The skid steer’s history goes back to 1957, when Louis and Cyril Keller, brothers from Minnesota, built a mini loader to assist a local turkey farmer in cleaning manure from the barn. This initial prototype was equipped with two front wheels and a rear caster wheel that made it possible for the machine to turn within the narrow barn aisles.

Melroe Manufacturing was intrigued by the Keller brothers’ invention, and this company later became the well-known Bobcat brand. In 1960, they introduced the M-400, the world’s first genuine skid steer loader with four-wheel drive and independent wheel control.

The design has been updated over time, and modern skid steers now come with:

- Fully enclosed cabs

- Air conditioning and heating

- High-tech hydraulics

- Joystick controls

- On-board diagnostics

Nowadays, the likes of Caterpillar, Bobcat, Case, John Deere, Kubota, and New Holland make diverse models of skid steer lifts. The design has passed the test of time and is an essential tool, just like it was more than 60 years ago.

Types of Skid Steer Loaders

Wheeled Skid Steers

Wheeled skid steer loaders are the most traditional and widely used type. They are fitted with four sturdy tires and are the perfect choice for tough, flat surfaces such as concrete, asphalt, and compacted soil.

Benefits:

- High travel speeds over solid ground

- Lower initial and maintenance costs

- More efficient fuel consumption than tracked models

Such machines are suitable for:

- Urban construction

- Indoor demolition

- Hardscape landscaping

- Snow clearing paved lots

But wheels have less grip on soft or rough ground, so they can get stuck or lose traction in mud or sand.

Tracked Skid Steers (Compact Track Loaders)

Tracked skid steers (a.k.a. compact track loaders or CTLs) are machines that have tracks made of rubber instead of wheels. This change allows them to have better traction and flotation; thus, they are more suitable for working on any kind of terrain that is not even, muddy, or snowy.

The benefits, for instance, are

- More traction in soft or waterlogged conditions

- Lower ground pressure (worn-out areas give less risk of contaminating lawn and other sensitive surfaces)

- More safety on slopes

On the other hand, if a job cannot be fulfilled without these types of machines, then tracked models are indispensable for such cases like

- Mud work on sloped construction sites or land clearance on inclines

- Tree-related activities and simply taking away unwanted vegetation

- Turf projects or soil that is not sufficiently binding/landscaping work on it

- Deep and/or ice-covered areas where snow needs to be removed

Some of the most important disadvantages of skid steers with tracks include:

- Considerably higher initial investment

- More expensive maintenance of tracks

- That can be a little slower than usual

But if the rough or muddy area is near your work site, the tracked skid steer is usually better than the wheeled one.

Mini Skid Steers

Mini skid steers, or stand-on skid steers, are super small loaders that are perfect for jobs with hard or very narrow access. They are the usual choice of:

- Landscapers

- Fence installation experts

- Irrigation system installers

- Innovative homeowners

Mini skid steers are slim enough to pass through residential gates or alleyways, and most of the time they include:

- Stand-on platforms

- Quick-change attachments

- Hydraulic auxiliary ports

Though small in size, these machines are

Perfect for:

- Mulch or gravel spreading

- Posthole digging

- Light trenching or grading

- Loading small trailers

Being small in size, they are less damaging to the turf and can be easily transported, usually by a standard pickup and trailer.

Large Frame Skid Steers

If you are looking for a strong lifting power and a large hydraulic output, large-frame skid steers are the machines that will meet your requirements. With these units, you can lift above 3,000 lbs, use heavy-duty powered tools like cold planers and stump grinders, and undergo hard commercial work.

The features are typically

- Enclosed cab with a pleasant atmosphere all year round

- Advanced digital displays

- Hydraulics with high flow

- A design by the weight that balances for lifting safety

Ideal for:

- Roadwork and asphalt cutting

- Heavy excavation tasks

- Large-scale demolition

- Snow clearing with 10’+ blades or blowers

They are more expensive, but for intensive work, large frame skid steers are capable of delivering great outputs and can be relied upon for a long time.

Key Components and Operation

Engine and Powertrain

Every skid steer uses a diesel engine as its core, which can range in production from 20 to over 100 hp; it depends on the size and class. These engines not only make the machine move but also drive the hydraulic system that powers the lift arms and attachments.

Few Things You Can Expect from a Diesel Engine:

- Turbocharged diesel is used for power and fuel efficiency

- New models are Tier 4 emissions compliant

- Starting the device and adjustingthe throttle were made as easy as possible with just simple controls.

The following features are included in the powertrain:

- Hydrostatic transmission—the reception of such turns as zero-radius is allowed

- Chain drive or direct drive systems

- Axle constructions intended to be strong under heavy stress

Taking care of the engine by itself is very important—making sure that oil, coolant, and filters are in good condition daily will prolong the life of the machine and save you a lot of money through unplanned stops due to a lack of maintenance.

Hydraulic Systems and Controls

One of the main reasons why the hydraulic system makes the skid steer so flexible and convenient is because it is the power source for the lift arms, tilt cylinder, and any other hydraulic attachments. Some of these are

- Auger

- Breaker

- Trencher

- Grapple

The two kinds of hydraulic systems are:

- Standard Flow – ~15–23 GPM (gallons per minute)

- High Flow – ~26–40 GPM, for more powerful attachments

Available options for controls:

- Foot pedals (traditional)

- Joystick controls (modern)

- Pilot-controlled assist systems (smooth precision)

Hydraulics are the lifeblood of a skid steer, so it is very important to keep the fluid level up and check the hoses regularly to make sure the machine will function safely and in the best possible way.

Skid Steer Tires and Tracks

The tire or track that best suits the job is what makes the performance different from the rest. Tires for the wheeled type of the skid steers are available in different kinds:

- Pneumatic tires—designed for common uses

- Foam-filled tires—can’t be punctured

- Solid rubber tires are heavy-duty and have a long lifespan

- Bar lug tracks—strong and sturdy, excellent for mud

- Block pattern—for smooth surfaces and little damage

- Multi-bar or zig-zag—an all-around hybrid for any terrain

Traction and tracks matter for:

- Traction

- Operator comfort

- Surface protection

- Fuel efficiency

It is always recommended that you use the tread that best fits your terrain for maximum performance and longevity.

Attachments and Customization

Common Attachments for Skid Steers

A skid steer is a multi-functional tool, which is among one of the most notable characteristics it has, as it can rapidly change between different types of attachments. The most frequented ones are

- Bucket (standard, 4-in-1, high-capacity): The right choice for loading, digging, backfilling, and grading

- Pallet Forks: The best option for lifting and moving pallets and heavy materials

- Augers: For drilling holes in fence posts, trees, and piers

- Grapples: Suitable for grabbing logs, debris, or demolition materials

- Trenchers: Good for digging narrow trenches for utilities or irrigation

- Sweepers/Brooms: For the cleaning of sidewalks, driveways, and job sites

- Snow Blades/Blowers: For the removal of snow in the most effective way during winter conditions

With these attachments, a basic skid steer is transformed into a loader, dozer, forklift, backhoe, and so on—all in one compact machine.

Specialty Attachments for Niche Applications

Besides the regular tools, a wide range of special attachments is available to meet the needs of the industry-specific market. Here are some of such cases:

- Hydraulic Hammers: Road breaking is usually done using these hammers.

- Cold Planers: Are used for the asphalt milling and road repair process

- Stump Grinders: Are the machines that landscapers and tree removal services operate

- Concrete Mixers: Makes on-site mixing and pouring of concrete possible

- Tree Spades: Are the machines for moving trees and shrubs only

- Soil Conditioners: Are used for seed bed preparation or landscape renovation

Those tools are designed to make operations easier and faster. Basically, the operators can switch between tasks quicker and more accurately; therefore, there is no need for larger single-purpose machines anymore.

Quick-Attach Systems and Compatibility

Nowadays, skid steers are equipped with a universal quick-attach system that is most commonly referred to as “Bob-Tach” or “quick coupler” in accordance with the manufacturer. In most cases, the machine operators can change the attachments in under a minute without leaving the cab.

Key benefits are

- Hydraulic couplers installed for powered attachments

- Standard mounting plates that can work with most brands

- Mechanisms for locking that can be manual or powered

Basically, the universal interface has changed the way the skid steers are utilized to a great extent. The user is allowed to adapt to almost all of the tasks that he/she could come across with one machine and countless tools during his/her workday.

Use Cases and Industry Applications

Construction and Demolition

The implementation of skid steers in the construction industry has reduced the work needed for site prep, grading, debris removal, and material transport to a great extent. Their turnability and small footprint give them the option of working inside buildings, moving through narrow alleyways, or operating around obstructions.

Common uses:

- Breaking concrete slabs or small destroying buildings

- Loading materials such as gravel, dirt, and rubble

- Dump trucks were loaded

- Foundations were leveled

With the proper tools, one person can do the wonderful works that were otherwise impossible without a whole crew.

Landscaping and Snow Removal

Landscaping the area is excellent with the skid steer application that is used to grade, move dirt, spread mulch, and dig. The small size of these vehicles helps to maintain speed and power and also helps to reduce surface damage.

Common landscaping applications:

- Grading and sod prep

- Planting trees with augers or tree spades

- Distributing of mulch and rocks

- Irrigation trenching

In the winter, if you need a different attachment, just change it for

- Snowblowers

- Snowplows

- Salt spreaders

Lawn care and property management companies use skid steers throughout the year.

Farm Work and Agriculture

Skid steers are farm animals freed from stress by:

- Moving hay bales and feeding

- Cleaning animal pens

- Digging trenches for water lines

- Handling bulk materials

Their functionality, sturdiness, and willingness to work wherever in a barn, in a pen, or in a feedlot—make them an irreplaceable part of everyday farm operations.

Dairy farms, vineyards, and nurseries, which have limited space and diverse tasks, greatly benefit from the use of mini and compact models.

Roadwork and Utility Maintenance

In the municipal and utility sectors, skid steers are eagerly sought for their portability, quick deployment, and ability to get into tight areas.

Tasks include:

- Pothole repair

- Road shoulder maintenance

- Cable trenching

- Concrete cutting

- Snow and debris clearing from sidewalks

Crews can tow a skid steer on a trailer, quickly release it, and do their work, which minimizes traffic disruptions and maximizes efficiency.

Advantages of Using a Skid Steer

Compact Size and Mobility

Skid steers are very maneuverable, and they can even take a zero-radius turn in a small area. They are usually employed in areas where the space is limited, for example:

- Urban construction sites

- Residential properties

- Inside warehouses or buildings

This mobility saves time, cuts down on manual labor, and increases job site flexibility—especially in instances where large machinery cannot fit.

Year-Round Usability

The application of a skid steer is not seasonal; the machine can perform any function in any climate throughout the whole year. Simply change the attachments to suit the machine to different weather conditions.

- Spring: Trenching, grading, planting

- Summer: Heavy lifting, demolition, soil conditioning

- Fall: Brush clearing, mulching, construction

- Winter: Snow blowing, plowing, salting

Furthermore, the opportunity to perform diverse jobs in different seasons makes them one of the most profitable machines in terms of ROI.

Cost Efficiency and Labor Savings

One operator along with an appropriate attachment will enable a skid steer to do the job of a crew of several workers, and thus labor costs will be reduced while the project timelines will be accelerated.

- Low idle time means more work done.

- Toggle fast-changeable parts allow for a lesser number of machines.

- This design allows for a more efficient use of fuel compared to larger loaders or tractors.

They are also more compact and therefore need less space for transportation and storage; in other words, the user has to pay less for the rental of the vehicle or for keeping it.

Limitations and Considerations

Load Limits and Stability

Despite their power, skid steers are subject to limitations due to their weight and the machine’s balance. Overloading or wrongly positioning the load can lead to:

- Tip-overs, which happen most of the time when the machine is engaged in a lift or located in an area with uneven ground

- Applying hardware on the hydraulic system due to the excessive load

- Lack of traction and steering control

Rated Operating Capacity (ROC) is just one of many important measurements that tell the machine how much it can safely lift. Most of the models can carry between 1,300 and 3,700 pounds, but ROC varies depending on:

- The height of the lift

- The size of the bucket

- Attachment type

- Weight distribution

Operators should always remember to keep the load low while moving, not to turn on slopes, and never to go beyond the manufacturer’s specs. For extra support, use counterweights or wide-track models when handling heavy materials.

Surface Damage and Terrain Limitations

Skid steers with wheels may lead to severe damage to the surface, e.g., when they are spinning on a lawn, soft ground, or some other finished surface. The combination of the solid grip of the tires and the skid-turning movement can cause the area to show signs of wear or develop grooves.

One of the most-cited concerns:

- ripping off the turf while landscaping

- Asphalt scuffing in urban environments

- Soil compaction on farmland

On the other hand, tracked models, although having higher maintenance expenses, are softer on the ground and less damaging to the surface, which is especially important for agricultural soils or any other types of soft natural surfaces. Always go for a machine and tire type (pneumatic, foam-filled, or solid) that are most suitable for the terrain. We assure you better traction and a longer life for your surface.

Safety and Visibility Concerns

Even though modern skid steers are equipped with various features that put safety and visibility as their main concern, security is always an issue—especially in crowded or small spaces.

Some dangers are part of it:

- Areas that cannot be seen because of the loader arms

- Dangers of overturning on slopes

- Getting trapped when changing attachments

- Pedestrian crashes in areas where vehicles and people share the space

Examples of safety improvements are

- Backup alarms

- Cameras

- Roll-over protection (ROPS)

- Flashing lights and reflective tape

Flashing lights and reflective tape are important safety features; however, the most crucial safety measures are operator training and site awareness. Also, regular communication between workers and clear visibility paths not only help in reducing the accidents.

Buying Guide for Skid Steer Loaders

New vs. Used

If you buy new, you will get the following benefits:

- Full warranty

- The latest technology

- Better fuel efficiency and emissions compliance

- No previous wear or damage

While used equipment can be obtained for a much lower price, it is accompanied by a number of risks. Therefore, when going for a secondhand machine:

- Have a look at the engine hours (less than 2,000 is perfect)

- Check the condition of the hydraulics, tires/tracks, and frame

- Try the responsiveness of the attachments

- Request maintenance records

Some used machines from reliable dealers may come with the provision of warranty extensions, financing, and service packages—perfect for small businesses or seasonal operators.

Evaluating Size, Power, and Hydraulic Capacity

The decision to choose the right skid steer is the art of balancing:

- Machine size and footprint

- Rated operating capacity

- Hydraulic flow (standard vs. high-flow)

Consider these questions:

- Do you need to work in tight spaces?

- Will you be using heavy-duty hydraulic attachments?

- What materials will you be lifting, and how high?

Compact models are successful in landscaping and urban work, while large-frame units have their strong points in construction, roadwork, and snow removal.

Best Brands and Models of 2025

Among others, these are the most famous manufacturers of skid steer in 2025:

- Bobcat—Iconic brand, known for reliability and innovation

- Caterpillar (CAT)—Rugged, powerful, and full-featured

- John Deere—Trusted in agriculture and construction

- Kubota—Small, productive, and easy on the budget

- CASE – Good dealer presence and wide application

- New Holland—Perfect for agriculture and snow clearance

Top Models in 2025:

- Bobcat S650—Excellent compromise between power and comfort

- CAT 262D3 – Very powerful hydraulics for the use of various attachments

- Kubota SSV75 – Very affordable and controllable

- John Deere 330G – Heavy sketch, weighty lift abilities

- CASE SR270B – One of the highest lifting ROCs in its class

For the best long-term ROI, pick a brand that has strong local dealer support, available parts, and good resale value.

Maintenance and Best Practices

Daily Maintenance Checklist

Performing daily maintenance is a great way to avoid breakdowns and keep your machine in good condition for a longer time.

Before each use:

- Check engine oil, coolant, and hydraulic fluid

- Check the hoses and cylinders for leaks

- Clean or check the air filters

- Check tire pressure or track tension

- Make sure that all the lights, horns, and safety features are working

- Check for cracks, rust, or abnormal wear

Just 10 minutes at the very beginning of each day can be a great time investment and will save you a lot of time—and money—down the road.

Long-Term Care and Servicing Tips

Long-term maintenance involves:

- Changing engine oil and hydraulic fluid every 250–500 hours

- Regular filter replacement

- Inspecting the undercarriage and tracks or chains

- Applying grease to all the joints and the pivot points

You could also do a couple of smart things:

- Keep records of maintenance issues and services performed

- Be sure to use Original Equipment Manufacturer parts only

- Plan your seasonal service before the weather changes drastically

If you take good care of your vehicle—inside the building, if possible—it will extend the life of the skid steer by keeping it from the elements and from getting tired.

Common Issues and How to Prevent Them

Common problems include:

- Hydraulic leaks—that result from the wear of seals and hoses

- Engine overheating—which is mostly caused by a dirty radiator and low coolant

- Electrical faults—that happen due to wires being exposed and moisture getting in

- Starter failure—that is caused by battery discharging and corroded terminals

Preventive measures:

- Carry out the necessary inspection regularly

- Wear the machine out within the limits of the prescribed functions

- Have the machine cleaned after working in a muddy or dusty area

- Store your machine in the right place after use

On-time repair and preventive maintenance will be the keys to having your skid steer in excellent condition and safe to use for a long time.

Operator Training and Safety

Certification Requirements

Generally, a formal license is not required to operate a skid steer on private property or your own worksite. However, operator training is still essential and is a must in commercial settings.

Most employers and contractors of the construction industry prefer to take the route of the OSHA training program, which provides the following:

- Safe operating procedures

- Machine inspection

- Proper handling of the load and stability

- Practice of Emergency stop and hazard response

Training programs can be done by means of:

- Vocational schools located in your area

- Online certification programs

- Equipment dealerships and rental companies

In certain places, you may be required to have a certificate or evidence of your ability, especially for work on a union or government site. By investing in quality and proper training, you not only assure legal compliance but also lower the chances of occurrences and equipment malfunction.

Safe Operating Procedures

Skid steer operators should always adhere to a standard routine of safe practices, which include the following:

- Before turning on the machine, check for fluids, tires/tracks, lights, and attachments.

- Use the grab handles and steps to mount properly; never jump in or out.

- Just before ignition, fasten your seatbelt and lower the safety bar.

- While moving, keep your arms and buckets at the low position.

- Drive slowly when close to people, slopes, or obstacles.

- In case you are backing up, do it slowly and carefully—use mirrors and cameras if you have them.

- Don’t make sudden turns or stops, especially if your load is heavy.

- Do not go beyond the machine’s rated lift capacity.

- Don’t ever let someone sit in the cab or bucket while you are carrying them.

If you follow the manufacturer’s instructions and the rules of your site, not only will you be safe but also everyone else around you.

Tips for First-Time Operators

If you are a beginner, it is a good idea to start slowly with the skid steer and practice in an open and level area. Here are some things that you can work on:

- Get familiar with the joystick or pedal controls; it might take you some time to get the hang of it.

- Practice turning tightly and stopping slowly

- The lifting and lowering of the boom without the machine tilting

- Attaching and detaching tools in a safe and proper way

Visibility and load control are common problems for many first-time users. Remember to:

- Travel with the bucket kept low

- Do not travel with loads at full extension

- Enter slopes or ramps with caution

Experience gives confidence. Consistent practice and smart use will turn a skid steer into your powerful extension.

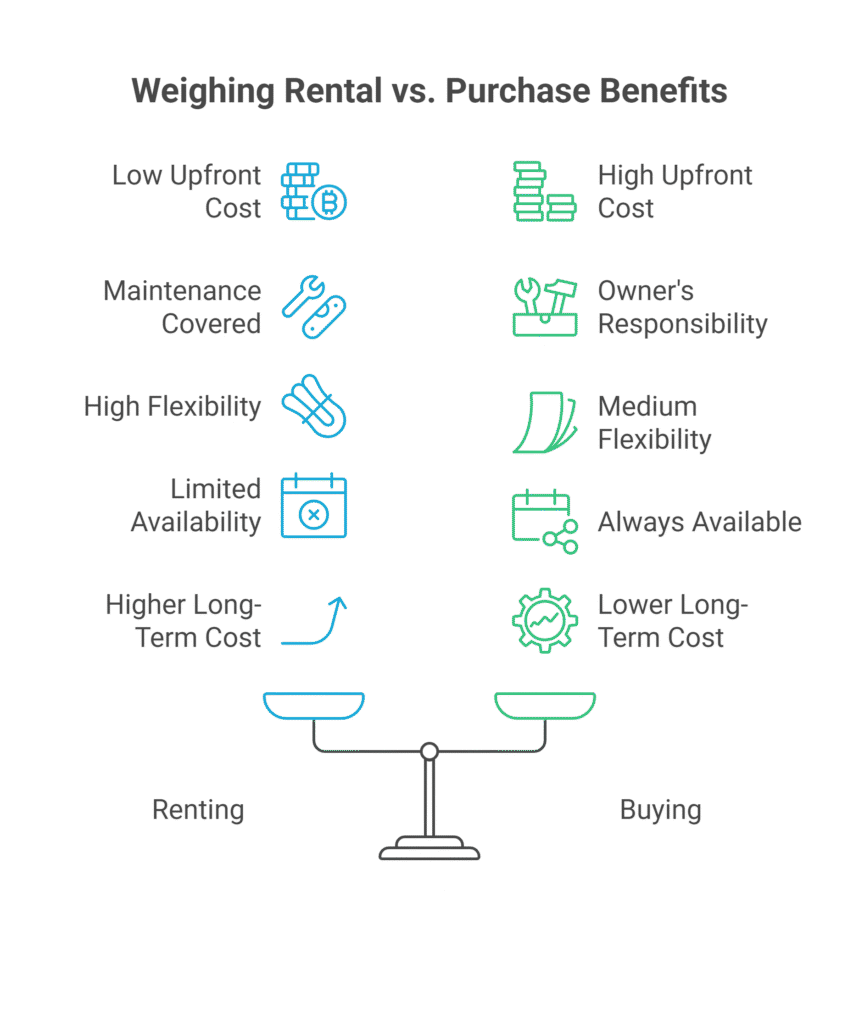

Renting vs. Buying a Skid Steer

When to Rent

Accumulating a skid steer is a great option for renting, including but not limited to:

- Working on temporary projects

- Seasonal jobs (landscaping, snow)

- Before buying testing of attached equipment or models

- Work that is limited to the usage of one attachment or a particular machine size

Renting’s advantages are

- A lower initial investment

- No worries about maintenance in the long run

- Always access to the latest models

The rental rates are usually between $200 and $500 per day depending on the machine size, location, and if there are any attachments.

Pros and Cons of Ownership

It would be better to buy a machine if you:

- Operate the machine regularly (more than 2 times a week)

- Want to have full access without having to go through a rental schedule

- Hold long-term contracts or have a stable seasonal demand

Benefits of ownership:

- Can be used at any time

- Lower long-term costs

- It can even be an asset or resale value by selling it

- Can be equipped with the owner’s preferred attachments

Downsides of ownership:

- Costs of maintenance and storage

- Greater initial investment

- Depreciation gradually

The majority of companies get the return on the skid steer within 12–18 months of regular usage.

Cost Comparison and ROI

If you are an occasional or varied user, renting might be more economical. For contractors or landscapers who use a skid steer 2–4 days per week, purchasing is generally more valuable.

Future Trends in Skid Steer Technology

Electric Skid Steers

Electric skid steers, like electric cars, have pretty much the same qualities; that is, they are silent, emission-free, and are gaining popularity steadily. Among the pioneers of such all-electric versions are Bobcat (with the T7X) and CASE (with the Minotaur EV).

Advantages:

- No emissions—ideal for indoor or city operations

- Less noise during operation

- Lower fuel and maintenance costs

- Government incentives and tax rebates

However, there are also challenges:

- Batteries last for only about 4–6 hours per charge

- Higher initial cost

- The repair/parts market for this relatively new technology is still developing

The electric models’ market share will gradually grow as the battery technology keeps advancing, with the trend most notable in cities, green buildings, and indoor demolitions.

Smart Controls and Automation

Modern skid steers are getting more intelligent, and they can be connected to the internet. Their new technical features comprise

- Touchscreen displays implementing diagnostics and telemetry

- Attachment identification that automatically adjusts the hydraulic flow

- On-board GPS as well as grade control systems

- Remote and partially autonomous control

The above-mentioned advancements facilitate:

- More appropriate use of time and fuel

- The work is not only safer but also more accurate

- Remote intervention and control from afar

As the technology progresses, there will be a bigger influence of the skid steers on the data-driven construction and digital job site management.

Final Thoughts

The skid steer loader is a machine that can and does perform miracles in construction, agriculture, landscaping, and utility work. Moreover, it is unparalleled in its multi-functionality and compact frame, and moreover, it is able to deal with a great many attachments (over 30). Thus, it is a must-have machine for contractors simultaneously requiring productivity, mobility, and performance.

If it is your first time purchasing a unit, or perhaps you are planning to upgrade the fleet, then the correct decision for a skid steer will be one that involves and takes into account the work types, terrain, usage frequency, and budget. A good-quality skid steer with the proper maintenance and training can be a great help to you, as it will give you safe and sound service for years to come and be a great asset for your business to grow.

While the industry is rapidly transforming towards the adoption of electric and smart machines, the evolution of skid steers is going to be continuous. Nevertheless, the essential characteristic of their total reliability stays unaltered, which is achieving more with less.