Maximize Efficiency with Skid Steer Trencher Attachment

The skid steer trencher attachment is a powerful tool that has brought about a significant shift in the way heavy maintenance work and trenching are conducted in a range of sectors like construction, landscaping, and utility installation.

The tool not only spruces up the efficiency of the skid steer but also is highly favoured by operators since the latter can dig the desired type of trench with little to no wastage of time.

Skid steers are very versatile and when they are coupled with the trencher attachment they become perfect machines for both contractors and landscapers.

The skid steer trencher attachment can now drive through tighter spaces, perform tasks that used to require larger machines and so on, hence definitely making a difference in the industry of earthwork equipment.

Along the conveyor line of a skid steer trencher attachment, the main part is vividly revealed as a rotating sharp-toothed metal chain, which is the cutting edge feature of this tool that allows it to slice through soil, rock, and any other materials.

The chain is set on a framework accompanied by the skid steer, thus giving the operator ease of use and high maneuverability characteristics.

Actually, the trencher can be configured in terms of depth and the width of the cut thereby giving it a wide door to many applications like the building of underground drainage systems or the cable laying service’s field.

Key Takeaways

- Skid steer trencher attachments are versatile tools that can be used for digging trenches in various applications such as landscaping, construction, and well as agriculture. influencers, manufacturers, suppliers, policymakers, practitioners, and community planners of critical sectors such as the information and communication sector, financial and banking sector, agriculture and natural resources sector

- The use of a skid steer trencher attachment can go a long way to improving efficiency and productivity on site, thus reducing the time and labor force required and therefore cutting down on labor costs.

- Skid steer trencher attachments are offered in different designs such as chain trenchers, wheel trenchers, and micro trenchers, each appropriately used for specific trenching operations.

- Before the operator picks the correct skid steer trencher attachment, he/she has to take several factors into account such as trench depth, trench width, type of soil, and job site conditions to ensure performing well.

Observing proper care and maintenance and sticking to safety measures in that way can only be regarded as the way of making sure that the skid steer trencher attachments have a long life.

Benefits of Using a Skid Steer Trencher Attachment

Efficiency is among the key advantages of using a skid steer trencher attachment.

Traditional trenching methods such as manual labor or the use of larger machinery are common causes of inefficiency on the job site saving time without having to accumulate the labor costs.

A skid steer trencher can be used to perform the trench digging activities quickly and in different required sizes of depth and width hence the job completion time would be very short.

The above efficiency, therefore, becomes the cost advantage to the contractors as they can do more work with their teams in a short time without losing quality.

The precision offered by the skid steer trencher is also one of the benefits. The user can set the parameters of the trench so as to enable him/her to work on the project with less of a hassle.

In such jobs as the installation of irrigation systems and laying of electrical conduits, where there’s a need for the exact measurements, the precision of the tool is paramount.

Another added advantage to the skid steer trencher is that there are less chances of soil disturbance since the attachment creates a shallow trench, which is increasingly absorbing the demand of planning and constructing new landscapes – a trend, thus limiting the loss of existing flora.

Skid steer trenchers are available in many types and each one of them is made to serve different users and situations. A common type that one can get is the chain trencher which employs a chain that is continuously rotating having teeth that break the earth.

This type has a variety of uses and is the most convenient for making the general type of trench. Its function is not limited to easy soil but can also work on challenging soil such as sand and clay.

The chain trenchers also can be easily adjusted with the various depths required and hence they can be used for both shallow and deeper digging. The other kind of skid steer trencher is the wheel trencher that uses a rotating cutting wheel to get through the dirt.

Wheel trenchers have higher speeds than chain trenchers and are consequently more useful in light soils. In contrast, they are much less effective in harder soils or rocks but are really efficient for projects that require high speed.

Moreover, there are trenching machines specially designed to work on specific jobs like rock trenchers that have strong-toothed cutters to dig in difficult geological sites or the vibrating trenchers that are best in breaking up the hard soil before excavating.

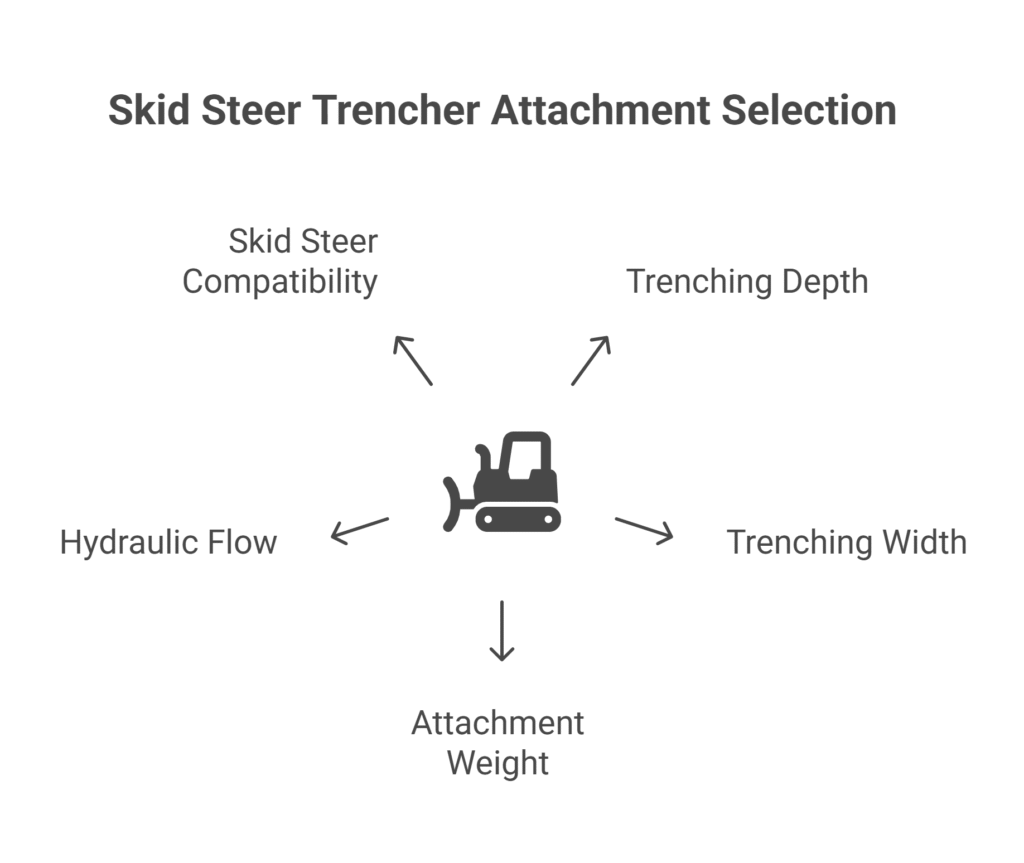

The process of selecting the best skid steer trencher attachment is a multi-faceted one and it requires there to be made several decisions that can indeed have a significant effect on the result in terms of both productivity and efficiency.

Foremost, the operator needs to be clear about the condition of the ground and which type of the trencher is suitable for that kind of ground.

This means that a project dealing with rocky or hard conditions will probably best be solved if a chain trencher that is very powerful and perhaps modified with blades not teeth is used.

On the contrary, for a soil type that presents no resistance, a wheel trencher is the best to go through the layers of soil quickly and without strain. Another significant point is the measurement of the trenches light up.

If this need is not met you might decide in favor of attaching the skid steer with an attachment improved for this use, such as precision cutters.

Moreover, the compatibility of the attachment and the skid steer model chosen by the operators must carefully be checked, thus ensuring that it is not inferior to the magnitude of the machine, with the weight, and thus can carry the power of the machine and finally perform perfectly.

Tips for Using a Skid Steer Trencher Attachment

For a skid steer trencher attachment to work at its best, operators need to be sure to follow the best practices when using it today. First, the first most important thing is to be well-acquainted with the machine controls and its tandem operation with the trencher attachment before the start of any project.

The knowledge of this procedure will help in unearthing the details of the installation of the right depth and width settings, thus, allowing efficiency as well as better results.

Subsequently, the walkthrough of both the skid steer and the attachment will further clear out any possible issues that might stand in the way of the performance.

One thing to remember while trenching is to commence at a lower speed and only after getting used to the operation then speed up the process.

It is this familiarity that indeed makes the entire project move faster and handles the trench size and depth more precisely. Also, the operators should always take care of their environment when they are working in an urban area or are close to other utilities.

By marking where the utility lines are first, your team can avoid problems like incidental damage and ensure protection throughout the project.

Maintenance and Care for Skid Steer Trencher Attachments

Regular Inspections

As the primary goal of the inspections is to discover if the chain or wheel teeth are torn, as well as if any part of the frame or any hydraulic component shows signs of damage, regular checks are mandatory. All these together will eventually improve the safety of the equipment significantly and reduce the possibility of an operational failure.

Lubrication and Greasing

One more vital part of maintenance is greasing of the attachments. Many trencher attachments have ridgy metal parts that need regular greasing to avoid being rough and tearing as these things move.

The people that work with the equipment should check the manufacturer’s instructions for the specific lubrication plan and the type of grease that should be recommended for their specific model, on a regular basis.

Cleaning and Debris Removal

Additionally, cleaning the attachment after using it can be a good practice to get rid of all the dirt and debris that may come as a result of the machine working and, thus, will lead to prolonging the life service of the equipment.

Safety Precautions When Using Skid Steer Trencher Attachments

Safety concerns should be at the top of the list when using skid steer trencher attachments or any other heavy machinery. Operators must wear adequate personal protective equipment (PPE) like helmets, safety goggles, gloves, and steel-toed shoes, in order to reduce the risk of injuries.

Before one starts with the work, first, all people around the area should keep the distance and stand far from reach to avoid unnecessary dangers.

A survey of the site should be carried out by the operators using skid steer trenching devices to detect underground utilities and other potential land issues that are unsafe for work before the project starts.

Furthermore, using ground penetration locators that can prevent hitting any underground lines during an excavation can help reduce these occurrences. Also, when there is continuous communication with the ground staff, safety is assured because everyone involved will be well informed of the activities and any change of plans.

Final Thoughts

The skid steer trencher attachment is a revolutionary development in excavation technology, burdening with top-tier efficiency and accuracy for different trenching tasks.

The skid steer trencher operator can be more productive and take fewer risks while learning about the benefits of this attachment, the various types, the corresponding selection criteria, the correct usage, the maintenance issues, and the safety measures.

As businesses are constantly changing and requiring more productive techniques for moving dirt, the skid steer trencher would definitely be the go-to equipment for 21st century construction and landscaping.}