How to Get the Most Out of a 3.5-ton Excavator

The 3.5-ton excavator is a multi-purpose machine that has won the hearts of the users in diverse construction and landscaping projects because of its small, yet mighty performance.

Being about 3,5 tonnes in weight, the excavator gives users the best of both worlds – the ability to work in confined spaces and the capacity to do the job they want. It is thus ideal for cities with tight areas, where its design makes it easy for users to load it onto a normal car and take it to the next place without having to use a special transfer vehicle.

The fact that the 3.5 t excavator is small in size means it can move freely in places like the backyards of houses or narrow alleys, where it is hard for big machines to get in.

The hydraulic system that the 3.5 t excavator comes with is the main reason it can undertake the various tasks from trench digging to heavy materials lifting. The digging depth is usually around 2 to 3 meters, which varies in different models and are customizable too.

It can be used in various works such as giving a house its footings, installing utilities, and earthmoving jobs. Moreover, the majority of the models are also equipped with a swivel arm technology that provides you with a better position with the bucket or any other accessory without having to move the whole unit.

- It’s very essential, while choosing attachments to the job, that you consider the specific requirements of the job and select those attachments that would make the work of the excavator easier and faster.

- First of all, for the highest possible efficiency of the machine, as well as its long life, the maintenance of the excavator has to be taken care of in the right manner. It should consist of regular inspections, lubrications, and repair work done on time.

- By using suitable digging and loading methods that are efficient, we can help to increase the output of activities, at the same time, the use of the machine will be less affected by wear and tear.

- As the operator of the machine, you will be able to do better if you take advantage of the technology and the various automation features. The benefits will be accuracy, efficiency, and safety.

How to Attach Proper Tools to 3.5 tonne Excavator and Get Job Done Easily is the main point the article is talking about. Much of the ‘can do’ virtue of this machine is due to its flexibility to accept a vast array of different tools in a bid to do just about anything to a different degree compared to the previous way of working.

Such equipments as different-sized buckets may be utilized for digging and scooping, hydraulic hammers for breaking, drill holes were by the use of augers, are just some examples. The selection of the attachment considerably can determine the performance of the excavator as well as the entire success of the project.

While selecting attachments, always take into account the specific work requirements. As an example, a standard digging bucket can do just fine if the task is digging in soft soil; however, for rocky or compacted ground, a heavy-duty bucket or a hydraulic hammer would be necessary in order to get the most desirable results.

Besides that, making use of machinery will also add to the productivism; by way of instance, an auger will make holes for fence posts or tree planting in no time, while a grapple will not only manage but also move large debris or logs in an efficient way.

Any operator who has knowledge of capability as well as limitation of every attachment will then be able to select the most proper ones for the doing of his particular task.

Just Upkeep and Maintenance for Peak Performance of the Machine

Part of the process in which it is guaranteed that a 3.5 t excavator functions well in a long run is regular maintenance. A poor maintenance routine can cause malfunctioning, which in turn will bring the machine to use more fuel; also little by little, it will provoke major repairs that will require costly servicing.

A daily maintenance can range from checking fluid levels of the engine oil, the hydraulic fluid, and the coolant of the machine, in addition, to the execution of a security check to filters and belts.

The workers should check whether the tracks or the tires to be used are in a good state, are without damage, and properly inflated or tensioned.

Apart from daily routine works, some part of the maintenance can be done periodically with routine times depending on the operating hours or the instructions from the manufacturers.

Firstly, excavators should be thoroughly cleaned; even though it might not look dangerous; gradually, dirt and dust can fester in the critical spots of the machines and this can lead to overheating or mechanical failure without the user being well aware of it.

Secondly, by employing such a stringent maintenance program and schedule, operator-turned-device, the operator himself, can not only guarantee and cause the long life of single pieces of equipment but also set the stage for the equipment to perform at the highest level,…

Implementing efficient digging and loading techniques

Efficient digging and loading are the most important to achieve the highest productivity while the 3.5 t excavator is operating. Just one of the factors is knowing the extent of the machine and the radius of swing to be able to minimize the movements that are not necessary.

The machines should be positioned in a way that will be the most beneficial to the area of the work at the same time, it will be the least possible repositioning of the excavator.

For example, if one were to dig a trench, the motion of the digger would be the least if one starts at one end and works towards the other instead of starting in the middle and moving to one of the ends so as to be able to continue digging.

Another significant factor in the efficient working process is the hydraulic control system and its proper operation. To be more productive and less worn are, of course, a side effect of the smooth and accurate movements of the machine’s.

The use of the rig’s turn lever completes the gain in speed and the handling of the materials also reaches the optimum level while the operator is preparing the next load.

Referring to this we can notice that the operation will flow without a hitch or brake in the shaft as the post holder will be locating the next project, taking the next position without having to stop the movement.

As a result, they are thus able to cut their working hours considerably by applying these methods in the field. In conclusion, the operators will be able to lessen the time they spend on a particular site by almost, if not, double when they are able to adopt these tactics in their everyday activities.

Lastly, by applying these techniques in fieldwork, the operators will not only improve their efficiency but they will also be able to finish their work much faster.

Utilizing technology and automation features

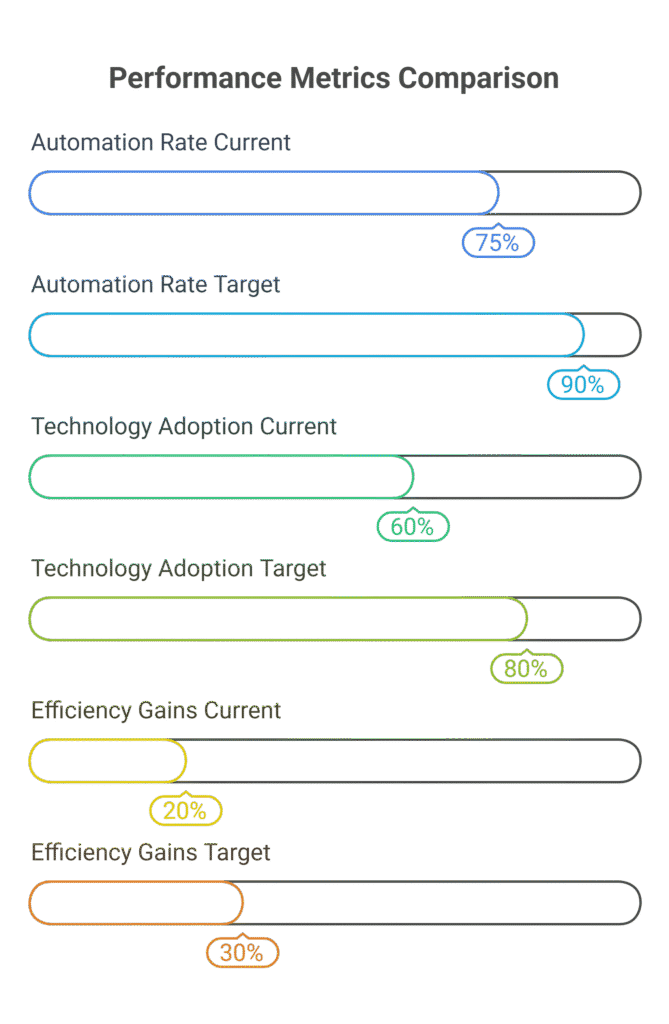

Technology adoption has completely changed the way operators carry out their works in the case of modern excavators. One of the major changes in 3.5 t excavators is the introduction of technology where GPS system, telematics, and automated controls can be counted among the highly advanced features that assure accuracy and efficiency of work.

By employing GPS technology, the operators can get an accurate layout of the site that will serve as the base for digging the right depth and dimensions without causing a lot of reworks.

Apart from saving time, this also minimizes the waste of materials. Besides this, telematics systems gather data in real-time on machine performance in which fuel consumption, operating hours, and maintenance needs are included.

Fleet managers can take advantage of this information to decide which equipment and when the maintenance schedule should be. To make things easier for the user, there are certain models providing automated features that aid in tasks such as leveling or grading by using sensors that help in maintaining the same depth and angle of the surface during the operation.

By integrating these areas of technology, operators are made capable of achieving perfection and being efficient at the same time.

Planning and organizing the work site for streamlined operations

One of the most important parts of the whole process that determines whether the use of a 3.5 t excavator will yield the desired results is planning and organizing the work site effectively.

Before starting any work on a project, a site assessment should be done in which difficulties like the presence of underground utilities, soil conditions, and access points are identified.

Equipment positioning and workflow strategies that help in reducing disruptions will be decided based on the information gathered from this assessment. On the spot, marking off different zones for various activities is a way of utilizing time more efficiently.

Setting up areas for material storage, equipment parking, and waste disposal results in the maintenance of order as well as time saved that would have been used in searching for the necessary tools or materials.

Moreover, you’d probably get more done in less time if you prepared a flow chart outlining the steps to follow in your operations such as material transport after digging has been done. Giving it the time it needs to be done right will definitely give you a smooth work process without unnecessary delays.

Training and empowering operators for maximum productivity

The capability of workers is an important determining factor for how a 3.5 t excavator will be productive at the place. Equipping the operators with all the necessary knowledge and skills to safely and efficiently handle the machinery through fluently delivered training programs is a must. Training needs to delve not only into basics of operation but also to advanced skills like attachment usage, maintenance, and safety practices.

Continuing education of operators will build a culture of continuous improvement among the workers. Participated by the operators, the adoption of the best methods and the discovery of productivity-enhancing techniques can be done smoothly.

Similarly, having the certification or the specialized areas of training such as advanced excavation techniques and safety management further enhance the capabilities of an operator.

By committing to investing in operator training and empowerment, companies will be able to reap the full benefits of their equipment which in turn will guarantee safety and efficiency on-site.

Monitoring fuel consumption and reducing unnecessary idling

Fuel consumption is one of the major items on the list of operating costs for a 3.5 t excavator. Thus, careful monitoring of the use of fuel will keep the project profitable.

Operators need to be equipped with the skills to spot the main reasons of high fuel consumption, such as aggressive driving habits and long idling periods. Implementing the strategies for fuel-use minimization will lower the operating expenses, and will also contribute to the preservation of the environment.

An idling policy is one popular way of setting a limit on the times when the machine can be in idle mode. Thus, the operators should be obliged to turn off the engine during long breaks or at times when they are not engaged in any work.

Besides, the use of telemetry for fuel consumption can give detailed information on the use of fuel which allows fleet managers to be able to spot inefficiencies or areas where improvement is possible.

Part of regular maintenance also promotes fuel efficiency; having clean filters and proper performance of the components can lead to a general better fuel economy.

As a result, if a company is committed to fuel consumption monitoring and is determined to combat fuel wastage through implementation of the relevant strategies, it will be able to increase its operational efficiency and effectively curtail fuel costs.