Enhance Efficiency with Mini Digger Attachments

Mini diggers, or compact excavators, have changed the face of construction and landscaping by introducing a versatile and efficient way of digging and handling materials. Their design makes them suitable for use in tight spaces where big machines cannot move. Nevertheless, mini diggers only get their full power when different attachments are used to extend their functions.

With mini digger attachments, the operator is capable of executing a broad range of job site tasks such as digging, grading, demolition, and material transport.

The existence of a wide variety of mini digger attachments in the market is a further advantage of these versatile machines. Every attachment is made to be used for a specific purpose and this allows the operator to adjust their machinery to meet the unique requirements of the projects.

This flexibility not just boosts the output but also lowers the need for different machines, thus cutting down the money that would have been spent on machine hire or purchase. Knowing about different kinds of attachments and their uses will greatly help in achieving and even exceeding efficiency and effectiveness with mini diggers for any type of work.

Key Takeaways

- Mini digger attachments are extremely versatile tools that can be used in various construction and landscaping projects.

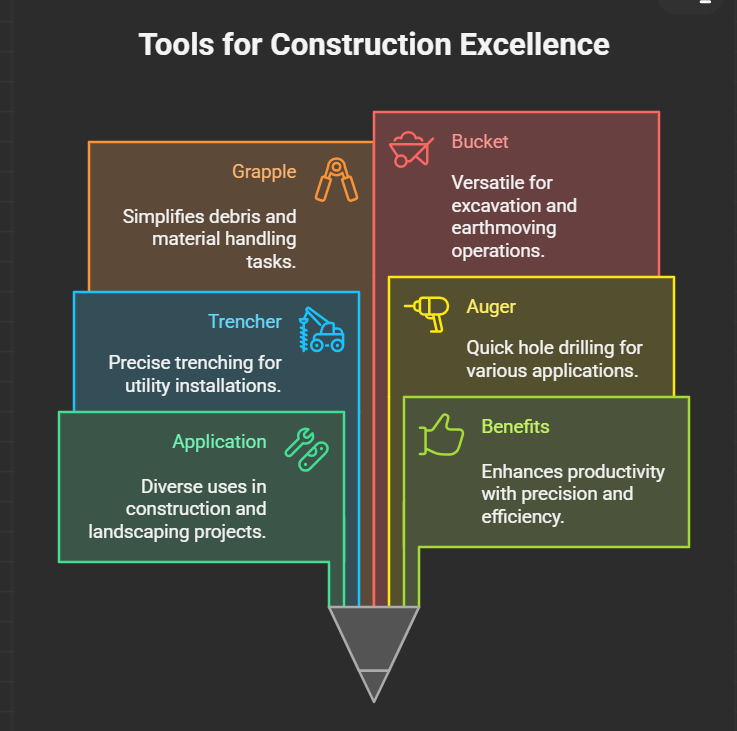

- Different kinds of mini digger attachments consist of buckets, augers, rakes, and breakers, with each of them having a different function.

- By using mini digger attachments the efficiency, productivity, and precision in task completion can be raised.

- While selecting the perfect mini digger attachment for your work, soil type, excavation depth, and specific task are some of the factors you need to ponder over.

- Giving the mini digger attachments the right maintenance, care, and also the safety measures will go a long way in ensuring their lifespan and efficient performance are maximized.

Types of Mini Digger Attachments

Various forms of mini digger attachments are available for different applications. One of the frequently used is the bucket attachment which can be found in different sizes and shapes like standard, trenching, and grading buckets.

Standard buckets are suitable for general digging and material handling, whereas trenching buckets are narrow and made for cutting deep and narrow trenches for utilities or drainage systems. Grading buckets, conversely, have a flatter form that facilitates accurate grading and leveling of areas.

Besides buckets, mini diggers may have hydraulic breakers that are needed for demolition jobs. These tools get their power from hydraulics and deliver rapid and powerful blows, thus are used for breaking concrete, asphalt, or rocks.

The next widely used attachment is the auger, which is an instrument for making holes in the earth for fence-posts, trees, or foundations. Augers may also be in different sizes so that they can fit holes of different diameters, consequently, they become multi-use tools that can be utilized in both landscaping and construction projects.

The inclusion of additional attachments for a mini digger such as grapples for the handling of large stuffs like logs or debris, rakes for removing brush or debris from a work site, and tilt buckets that permit the operator to have better movement during grading are just few examples of how a mini digger can be transformed into a multi-functional tool.

Every attachment represents a different function, and also the mini digger’s capacities can be elevated to a great extent by such kind of equipment to make it capable of handling various jobs with the same one tool.

Benefits of Using Mini Digger Attachments

The main benefit of employing mini digger attachments is their potential to significantly increase work productivity by job-site personnel. By simply equipping a mini digger with desired attachments, one can in effect do much more work in lesser time than correspondingly by manual labor or less specialized equipment.

As an example, the time which is used otherwise for concrete busting through heavy manual methods like using sledgehammers or jackhammers can be massively shortened with the aid of hydraulic breaker attachment.

Furthermore, the usage of mini digger attachments extends positively on to the contractor’s pockets too through the issuing of several measures revolving around cost savings thus made possible by the said utility.

Feat by a single machine able to accept various functions, the contractor therefore can minimally go for renting or purchasing the heavy machinery while excessive labor requisition is cut furthermore controlled.

This multi-functionality also implies the minimum number of machines on site thereby resulting in a decrease of transport and maintenance costs. Besides this, the accuracy resulting from the usage of specialized attachments may cause lesser material wastage and more precise project outcomes, consequently costing less.

Also, we cannot overlook the positive impact on safety that is introduced with mini digger attachments plus availability. Most of those operations that are generally performed manually may turn out to be quite dangerous because of the possibility of injuries caused by heavy lifting or usage of power tools.

And, by employing solely task-specific attachments, operators hence can diminish their physical exertion as well as the probability of accidents happening at the workplace. This action not only guards the workers but also fosters a more efficient working process since tasks can be accomplished without the inevitable stoppages caused by workers’ injuries.

How to Choose the Right Mini Digger Attachment for Your Project

The correct choice of the right mini digger attachment for a given task should be guided by a careful weighing of factors. First of all, one must figure out the tasks that have to be done. In case the trench for utility lines is the purpose of the project, then a trenching bucket would fit the job better than a standard bucket. On the other hand, if the task is grading or leveling, then a grading bucket or tilt bucket would be more practical.

Moreover, an important factor is the size and the lifting capacity of the mini digger. Every attachment has certain compatibility requirements that are based on the hydraulic power and weight class of the machine.

One has to be very careful to check the specifications of the manufacturer’s manual to be sure that the selected attachment can be operated safely with the mini digger you have. When a machine is overloaded with an attachment that is not compatible it can eventually result in mechanical breakdowns or safety hazards.

Furthermore, it is essential to take into account the land and soil conditions when thinking of what attachment to choose. For example, hard, rocky soil will require a robust hydraulic breaker or a heavy-duty bucket to get the job done whereas soft soil will make it possible to use lighter attachments without loss of efficiency.

By understanding these factors, operators will be able to make correct decisions which will not only improve the effectiveness of their work but will also ensure their safety.

Tips for Properly Using Mini Digger Attachments

If the operator wants to fully utilize mini digger attachments, he must follow the correct methods while operating them. A major tip would be to know fully the attachment before starting the work. Every attachment has different characteristics and usage instructions; comprehending these can help avoid wrong usage and bring about better results.

For instance, when using an auger, the operator must be informed on how to regulate speed and pressure to get the desired result and at the same time avoid the equipment from being damaged. Another significant point is the operator of the machine keeping the command of the mini digger at all times during the use of the attachments. The operator must be sure that they are rightly positioned and have a firm hold during the period of the operation.

The steadiness becomes very important especially when one is using heavy attachments like hydraulic breakers or grapples because wrong positioning can lead to loss of control and therefore accidents.

Moreover, the operator must be careful and make sure no obstacle is close or persons around before operating the attachments. Communication between the members of the team present on-site and who are involved in the work can also bring about safety and time-saving when one is using mini digger attachments.

The establishment of the signs or the use of two-way radios help to coordinate the movements and keep the communication lines open among the team members. The practice not only diminishes the possibilities of the incident occurrence but also effortlessly keeps the work going on since team members are anticipated with each other’s actions.

Maintenance and Care for Mini Digger Attachments

The right care given to mini digger attachments is what will determine how long and how well they will beable to perform. Periodically, the equipment parts that are most put under pressure like hydraulic hoses and pins, should be checked for signs of wear and damage. In case of anything like leaking or fraying, the matter must immediately attend to so it will not break further or cause the machine to fail.

After work, the running of the attachment is also quite important. Through process, dirt, mud, and other things may get on the attachment which later on can cause rusting or other mechanical problems if not cleaned in time.

The user should also spend the time thoroughly cleaning every part of the attachment especially the parts that move and that lubrication may be needed. The said work not only prolongs the lifetime of the machine but also permits easy handling when the next work comes up.

An additional crucial point to consider in maintenance is the fixation on the maintenance schedules that the manufacturers propose. Many manufacturers provide specific recommendations such as intervals of lubrication, inspection frequencies, and in the replacement of parts. Following these recommendations eventually keeps the machine in good working order and is less likely to break down unexpectedly during those phases of the project that are most critical.

Safety Considerations When Using Mini Digger Attachments

Safety must be the first thing to be considered when mini diggers with attachments are operated. The operators should put on the appropriate personal protective equipment (PPE) like safety glasses, gloves, hard hats, and safety shoes. Such equipment serves as protection against the probable hazards that are connected with excavating and at the same time minimizes the chances of getting hurt if any accident occurs.

In addition to PPE, the operators should initiate a safety check of both the mini diggers and the to-be-used attachments before starting work with them.

The safety check should be thorough and comprise a look at the hydraulic connection for any signs of leakage, a check to see if all safety guards are in their places, and testing of all the controls to make sure they are working smoothly. Any problem that comes up during the check should be fixed before work starts.

Besides that, the operators must be well informed about the safe procedures of operating an attachment and should know only what to do in an emergency.

That training not only imparts the knowledge on how to handle the equipment but also gives information on the steps to take in the event of an emergency. Knowing how to safely detach an attachment or switch off the machine when there is a malfunction can help in avoiding accidents and injuries on the site.

Maximizing Efficiency with Mini Digger Attachments

To sum up, mini digger attachments are an indispensable feature of compact excavators‘ versatility and efficiency enhancement across different sectors.

The understanding of the various types of attachments and their particular applications that the operators have helps them in the selection of the most appropriate tools for their projects.

The use of these attachments brings about the productivity to be made on the sites are only part of the benefits; also, cost savings and improved safety are other contributions that they make. Right attachment opting comes from thorough consideration of requirements of the project, compatibility of the machine, and conditions of the environment.

The correct handling of the equipment along with the faithful adherence to the maintenance schedule will keep these valuable tools in good working order for a long time. When safety measures are given priority during the operation, contractors can, at the same time, create a safe working environment and achieve maximum efficiency through the strategic use of mini digger attachments.