Maximizing Efficiency with Compact Excavators

A round in brief with compact excavators: it should not be surprising that their development has become a major success in the fields of construction and landscaping.

These monsters are equipped to function in restrictive situations where bigger excavators are out of the question. They are not weak because of their smaller sizes, and it is well known that several compact excavators have modern hydraulic systems that are capable of lifting and digging.

Because of this, they are suitable for work like trenching, grading, and site preparation, which require accuracy. One more good thing about compact excavators is that they are very simple to take from one place to another.

Compared to full-size ones, they are lighter and hence usually can be hauled by an ordinary pick-up truck or carried on a trailer without the necessity of getting permits.

This mobility permits technicians to relocate places quickly with less time vehicle and thus spending more working hours. Besides, most of them are manufactured with easy-to-understand controls and simple operation, thus accessible to operations at different levels of skill. These features – power, portability, and simplicity of usage, – make them core elements in the field of modern construction and landscaping.

- Compact excavators provide increased maneuverability and flexibility in limited areas, thus being perfect for various construction and landscaping projects.

- While selecting a compact excavator suitable for the task, you should take into account the size of the work area, the type of the material to be excavated as well as the depth and reach of the digging needed.

- Good maintenance and caring of compact excavators such as regular checks, lubrication, and cleaning will definitely prolong the life of the machinery and ensure its proper functioning.

- To be able to use compact excavators in a safe and effective manner, operators need to undergo thorough training, follow safety rules and always watch their surroundings.

- By means of such attachments as buckets, hammers as well as augers, the ease of use and the productivity of compact excavators can be elevated which in turn will enable them to handle an expanded scope of work.

Choosing the Right Compact Excavator for the Job

The choice of the most appropriate compact excavator for a given task requires the evaluation of numerous factors among which the size, the weight, and the capabilities of the machine should be foremost considered.

First of all, one needs to examine the conditions of the work site. If, for example, the project requirements dictate that the work be done in very confined areas or should be carried out on uneven ground, then a smaller model with less width and a lower center of gravity would probably be the right choice.

On the other hand, if it is necessary to do heavy lifting or a large amount of digging, then it would be better to invest in a more powerful model with a stronger hydraulic system. The potential uses for the equipment in question are a very important factor that should not be overlooked.

Most of the compact excavators are equipped with multiplicity of attachments such as buckets, augers, and grapples which can be connected to enhance the overall function of the machine.

When making a decision about a unit, it is very important to establish that it will be able to carry the required attachments needed for the execution of certain jobs.

The ability to extend the arm and the depth to which the digging can be done is equally important; for instance, some works might require a deeper excavation than others thus a machine with longer arm capabilities will be needed.

Proper Maintenance and Care for Compact Excavators

It is of great importance to keep a compact excavator in good health if one wants it to operate efficiently and last for a long time. Part of the regular maintenance should be keeping an eye on the oil and other fluid levels, checking the hydraulic hoses for any leaks, and always ensuring that the parts that move are well lubricated.

Furthermore, the condition of the tracks or wheels should not be neglected as the wear and tear of these areas will substantially affect the machine’s mobility as well as stability especially if it is going to be used on different kinds of terrains.

If all the work on the machine is kept up, then the machine not only will function better making it less likely to have unexpected breakdowns and the taking up of costly time will be reduced.

In addition to daily checks, it is very important for operators to follow the service schedules recommended by the manufacturer for more significant maintenance works.

This may refer to the changing of oil, replacing filters, and checking parts such as the engine and the gearbox. Being very thorough with the records of the work done on the machine can help the owner to see and understand the pattern and thereby, potential problems which can be fixed before they get too big.

Operators who prioritize maintenance and care can thus extend the life of their compact excavators while at the same time keep them as reliable tools on the job site.

Tips for Operating Compact Excavators Safely and Efficiently

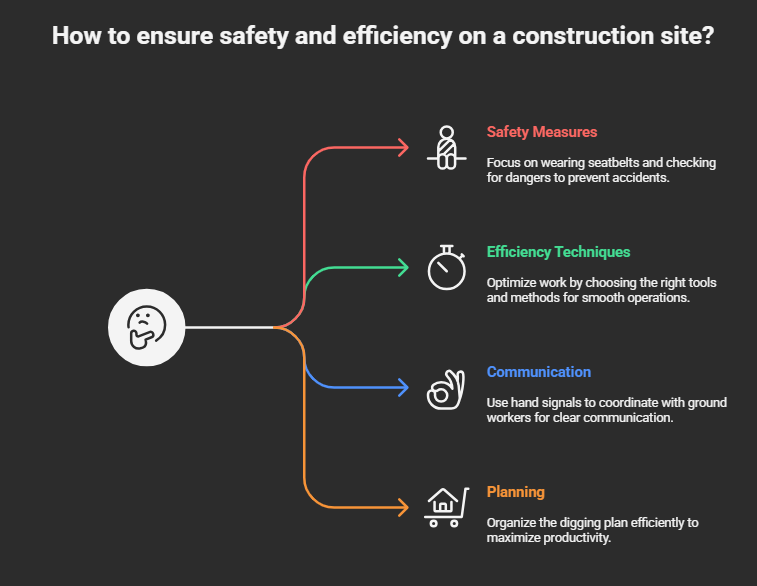

The operation of a compact excavator will entail a combination of skills, safety awareness, and following of regulations. A major point in safety is to make sure that all operators have been trained and are knowledgeable of the model and brand they are going to work with. Every device can have different controls or features which need to be studied before using them.

Apart from that, in addition to the necessary skills, the operators should always put on the appropriate personal protective equipment (PPE), for example, hard hats, gloves, and steel-toe boots.

This will help them in avoiding or minimizing the severity of the injuries that may occur. Efficiency may be reached through proper planning and correct techniques.

The first thing to be done before any operation is a thorough inspection of the work site which should be done by the operators themselves to spot any possible dangers like high voltage power lines or unstable ground.

The accuracy of the machine will be increased through the smooth and steady movements. Besides that, communication between the operator and the people on the ground must be maintained if they want to be safe and efficient. If safety and efficiency become a culture, then the workers’ output will significantly improve while the risk level will be lowered.

Utilizing Attachments to Increase Versatility

One of the main characters of compact excavators is that they can implement different attachments that allow-users to utilize them for different functions.

To illustrate, machines can be outfitted with different size buckets to dig and move materials, hydraulic thumbs to hold things, and augers to drill holes in the ground. Each piece of equipment is installed for a particular reason, thus completely changing the limited service capacities of one compact excavator into an infinitely multifunctional one.

For instance, the use of trenching bucket attachment enables workers to dig out very narrow trenches fast and easily for setting up utilities or drainage systems.

Likewise, an attachment called a grapple can be extremely helpful for the movement of large rocks or debris that are part of the landscaping process.

The ability of rapid change from one attachment to the other not only saves the valuable time but also maximizes the return on investment for the contractors who are heavily dependent on these machines for various projects. Knowledge of which attachments to be used for certain jobs can greatly increase productivity and the operator’s business can be extended to more services.

Best Practices for Compact Excavator Productivity

To get maximum results from compact excavators, the operators have to follow certain best practices that lead them to work more efficiently and with less breaks.

One of such good tactics is to schedule the work sequences properly before starting the jobs. The efficiency of the operators can be lifted to a higher level by doing all sorts of digging first and then moving on to grading, thus also cutting down on the unnecessary movements of the machines.

Apart from doing an excellent job sequencing, having a well-organized workplace also makes a huge difference and is very important for productivity.

Not only does it allow operators to strictly concentrate on the work with less interruption but also ensures that the required materials are at hand and the routes are clear.

Besides, regularly talking to coworkers about the work already done and possible problems is also a way to make the work flow better. When a good team spirit is established with everyone being informed about the targets and the expectations, productivity will be at its peak level for the whole team.

Maximizing Efficiency in Tight and Confined Spaces

With compact excavators, it is possible to do engineering works in very cramped spaces where are the question of making the maneuver by larger machines does not arise.

However, in order to accomplish the task efficiently in such an extremely restricted environment, different methods are required that are precisely designed for handling limited spaces.

A point of emphasis for the operators is to know all about the size and the capabilities of the machines so that they can move around the obstacles safely and still keep their productive efficiency at a high level.

The idea of just one part of the excavator can turn completely around independently of the rest of the chassis can be utilized as a way by the operators to get rid of the process of repositioning the whole machine continuously in order to dig or dump the materials.

Also, the exactness of the actions dealing with the limited area can help to avert the destruction of near structures or utilities. Besides, using smaller size attachments is also an option that can help in solving the problem of intricate work and still not losing in stability or control.

Incorporating Technology to Improve Compact Excavator Performance

The use of technology in compact excavators is a major novelty that has brought about a stunning change in their performance and operational efficiency.

Very many current models boast a whole array of features with one of them being telematics systems that collect and then transmit data on machine operation, consumption of fuel, and services required. Having such information by the users empowers them to make wise decisions concerning the use and the service of the machine thereby resulting in productivity being uplifted.

On top of that, progress made in automation technology has led to inventions of such features like grade control systems with which operators are helped in attaining accurate excavation depths without making manual adjustments all the time.

This technology relies on sensors and GPS to pick up exact grading levels and thereby giving minimum room for error and hence less redoing work which is costly and time-consuming.

The welcoming of such technological breakthroughs will definitely help the operators to do their work much faster while at the same time being assured of high-quality results for each project.

In summary, compact excavators are powerful and reliable tools in the hands of construction and landscaping workers of the 21st century and adaptable to various

environments. By learning about their advantages, choosing the right one for the job, taking good care of them, operating them safely, making good use of attachments, following best practices to be productive, finding ways to be efficient in a confined space, and using technology in operations, contractors can use these machines to get excellent results in a wide range of projects.