Enhance Skidsteer Performance with Quality Tracks

In the world of heavy equipment, the importance of good quality tracks for the skidsteer, is something that you cannot ignore. Tracks are the machine parts that come directly in contact with the ground and therefore it influences not only mobility but also the whole performance and efficiency of the machine.

Well made tracks are designed to be able to survive in different sorts of ground conditions, starting from muddy constructions sites to the rocky fields.

They give out the required grip and stability to the operators to thus efficiently handle the situation and furthermore making sure that the work gets done both in a safe and efficient way.

The sturdiness of these tracks is in fact closely related to the lifespan of the skid steer as bad tracks can make the machine put on an increased wearing and tearing of the parts.

Besides this, good quality tracks also have a positive effect on the comfort and safety of the operator. Security is upgraded considerably when the machine is reliable as, in other words, the risk of accidents caused by slipping or loss of control are minimized, and this happens mostly at difficult conditions.

This steadiness, in return, benefits the operator as well as the equipment and the surrounding space. Basically, quality tracks are simply a performance issue, but at the same time, they are a safety, productivity, and machinery lifetime extension commitment.

Key Takeaways

- Quality tracks are the life of the skidsteer which is necessary not only for the best performance but also for the machine to last longer

- The change to quality tracks can deeply affect the general performance of the machine as it becomes more stable and gains better traction

- The first thing to think about when buying quality tracks will be the track material, the tread pattern, and the durability

- Top-grade tracks not only elevate the functionality of skidsteer machines but also by eliminating the loss of power, optimizing the grip, and enabling the machine to operate at its fastest rate

- Inspection on a regular basis is highly recommended as it extends the life of top-quality tracks and ensures that the skidsteer performs at its best

- The number and model of the skidsteer as well as the job and the nature of the ground dictates the selection of the proper size and type of quality tracks.

- Quality tracks can be cost-effective in terms of the following: initial purchase price, long-term durability, and potential savings on maintenance and repairs

- Measures to get the most out of quality tracks for skidsteers are dealers with good reputations, producers, and e-tailers

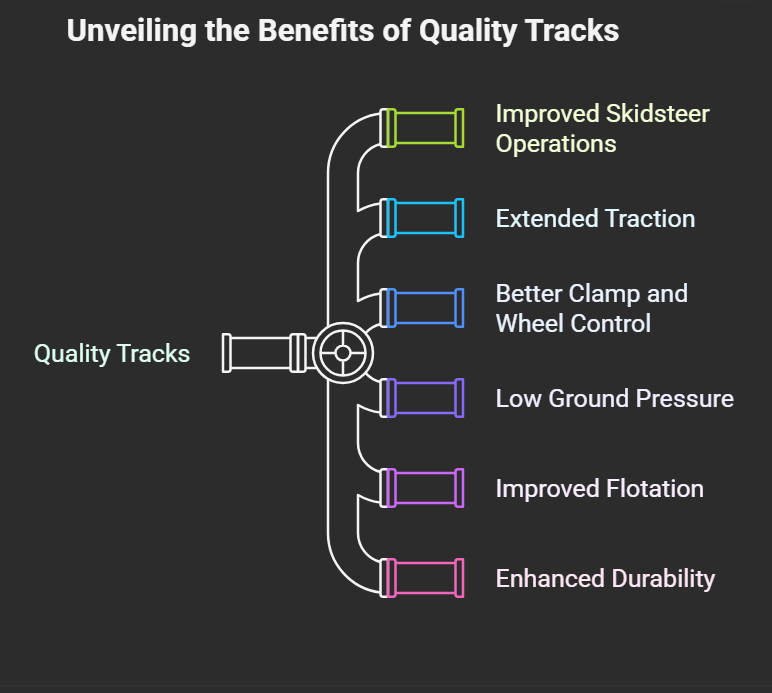

Benefits of Upgrading to Quality Tracks

Benefits of upgrading to quality tracks are not limited only to performance improvements but extend over a wide range of areas. A major one among them is better traction.

In reaching this goal, they are using innovative and optimal compositions of the materials as well as the tread pattern of the tires helpful in providing grip over different grounds encountered.

With the help of this improved traction, operations are now much easier as the starting and stopping of the machines can be managed in a better way especially on slopes and where the ground is of a slippery nature giving the operator the feeling of being in control of the situation.

Take, for example, a skid steer with high-quality rubber tracks that can easily run through a muddy work area without being immobilized and as a result, the whole work process will turn out to be more efficient.

Apart from the benefits of traction, these quality tracks also become quite durable most of the time. Such tracks are made of wear-resistant materials which consequently keeps the tracks in a good condition for a long time, and hence, the machine will seldom need to be taken for replacements and repairs.

What this durability means is that the total operational costs will be reduced over a period of time, which means that the clients can allocate the money they save on maintenance works and use it for productive hours.

Moreover, there are many that are even designed to be almost impervious to punctures and abrasions, and this is really a great idea which is helpful in cases where there are a lot of sharp things on the ground.

Total savings over a long period of time as a result of reduced downtime and the need for less maintenance make the decision of taking quality tracks a good investment for most businesses in the long run.

Factors to Consider When Choosing Quality Tracks

While choosing quality tracks for a skid steer, the factors which are essential and must be considered are numerous. Among them, the terrain type comes first.

Each different terrain needs its track to be adapted; thus for example, a machine working always on soft ground will have the most significant advantage of wide tracks that are distributing the weight more evenly and as such lowering the ground pressure and avoiding the sinking.

On the other hand, narrow tracks may be the most suitable for hard surfaces where you can focus on the advantages of easy maneuverability. The next question is what material the tracks will be made from.

Tracks consisting of high-grade rubber or composite materials generally offer more flexibility and keep environmental factors in check like solar radiation, and temperature changes.

More so, the treadmill pattern of the tracks should also be taken into consideration by the operators. Penetrative tread designs can offer you more grip in mud or gravel, whereas the polished ones will be the ones you should go for asphalt roads. These considerations will lead to consulting the right questions and the seeking of precise answers on the problem.

How Quality Tracks Improve Skidsteer Performance

Skid steering performance is largely dependent on the quality of the tracks. Good tracks not only increase mobility but also improve the overall efficiency of the machine in its various applications.

For instance, when operating, on an uneven, or rocky ground, good tracks provide maximum contact with the earth which means better stability and control. This stability enables the workers to use precise methods while grading and digging, which, in the end, will lead to better-quality work results.

Furthermore, high-standard tracks can be a great factor in fuel savings. If a skid steer is running smoothly due to the best traction and the stability required, less power will be needed to complete the tasks.

This not only brings down the costs for the use of the machine but also benefits the environment by cutting the emissions that come from the fuel consumption.

In such situations where time is money like building work with tight deadlines, the improved efficiency with the aid of good tracks can not only end the job quicker but also enhance the profitability of the business.

Maintenance Tips for Quality Tracks

For tracks of good quality to give their best and long-lasting performance, regular upkeep is a must-have habit. At the top of the list of maintenance activities is a regularly scheduled check-up to look for signs of wear or damage.

The operators have to frequently examine the tracks for cracks, rips, or any other possible deteriorations that may threaten the track’s strength. The prompt discovering of problems not only saves the skid steer but also makes sure it can perform its duties as usual.

Moreover, part of the care that is involved in the cleaning of the tracks after use, especially when the area is muddy or full of debris. The dirt and the trash that have been collected inside could cause the parts to become worn quickly and also lower their performance.

The operators should use a high-pressure water jet or a stiff brush to get rid of the dirt and debris that stick to the tracks and undercarriage. Additionally, it is very helpful to oil the parts that move within the track system as it will cut down the friction and wear that is the source of track life.

By doing the maintenance work that is described here, the operators will not only be able to get the best results out of the quality tracks but also guarantee that these tracks last long.

Choosing the Right Size and Type of Quality Tracks

One must choose the right size and the type of quality tracks first if desirable the best performance of the skid car would be achieved. First of all, the dimensions of the tracks should meet the skid steer model’s specifications; incorrectly sized tracks might cause the machine to work at malfunctioning levels or even get harmed.

Operators must seek out either the handbook or guidelines from the manufacturers of the equipment in order to know the right track size before buying one. Apart from the size, the question put forth before operators was what type of track would be their best operational partner.

To clarify, rubber tracks are predominantly utilized because of their flexibility and ability to provide substantial grip on almost all kinds of surfaces, at the same time ensuring low ground disturbance levels.

Contrarily, steel tracks might be more appropriate in the heavy application where absolute endurance is the most vital characteristic such as mining or demolition operations.

It will be a matter of operators reading the tape to fully comprehend the difference so that they can not only take the pack of their own necessities but also make a performance-leveling improvement possible.

Cost Considerations for Quality Tracks

In the decision-making process, if one is looking for the best quality of tracks, a factor that plays a major role and should never be ignored is the price.

It is true to western money, most of us will wish to avoid the high-cost route and instead be inclined towards the affordable tracks, but in the end, it is the other way around which shows high-quality tracks as the more economical way of use.

Less expensive tracks may save you the money for the initial part of the period; however, in the long run, they will be a cause for enormous maintenance costs. Which ultimately causes total ownership to be more expensive.

Further on in the same direction, we come across the point where operators are advised to look at the ROI (return on investment) that defines quality tracks.

Great performance can drive the company’s strength to higher levels by making it possible for more work to be done in less time, thus raising the income of the company.

While figuring out the costs, it is not only the starting price that should be considered but also the long-term savings brought about by less downtime and maintenance costs.

If operators adopt a all-encompassing stance towards cost considerations, they will be able to make financially sound decisions that are in line with their goals.

Where to Purchase Quality Tracks for Skidsteers

One of the most important things for the operators of skid steer vehicles is to find the places which are reliable sources where they can purchase quality tracks that meet the performance expectations.

The majority of the manufacturers are made to concentrate on the production of high-quality tracks that would be the best fit for different models of the skid steer. These manufacturers usually give detailed specs and compatibility info right on their web pages making it quite easier for the operators to find the right kind of options.

Besides direct buying from the makers, the operators can looks at the authorized dealers who supply the assortment of the quality tracks from various brands for the motor vehicles.

The dealers usually have the personnel who can be the right people to you for the selection of the proper tracks that would be the best for your requirements and the application.

Online marketplaces are another avenue for seeking quality tracks but the most important thing is to check out the seller’s credibility and the product’s authenticity prior to the purchase.

By traversing different paths of procurement, the operators are able to get quality tracks for their skid 4x4s which in turn help them enhance their performance and service life.