What is a Mini Excavator?

A mini excavator is a compact version of a standard one and is sometimes known as a compact excavator. Those weighing less than ten tons, as a rule, are highly efficient and are made for works that require a small place and accuracy.

Besides digging, mini excavators can cut trenches, grade, and even demolish, which, in turn, makes them the common denominators among contractors, landscapers, and utility workers.

Owing to their being small, they can do the job even in tight spaces where their big-sized counterparts are not fit to go. In short, mini excavators can be a good choice while working in narrow residential gates or congested urban areas.

However, in the case of size, their machines have many models that provide hydraulic systems that are capable of powering various kinds of attachments, such as augers, breakers, and grapples.

Compared to heavy-duty excavators that traditionally need to be moved using large transport and refueled, mini excavators can easily be moved with a trailer and even a pickup truck.

Small-business owners or independent contractors who are always on the move between sites will find this an added convenience or portability that gives them an extra advantage. Furthermore, their user-friendly design allows even the novices to operate them and is well-liked by the rental equipment providers.

Mini excavators might give the impression that they are a recent invention; however, as a matter of fact, their initial concept dates back to the time just after World War II.

The requirement for smaller and nimbler machines started when cities were expanding, and infrastructure projects were going local. Companies like Takeuchi and Yanmar, that is to say, the Japanese firms who invented and introduced compact design in the 1960s, have been credited with developing the first-looking mini excavators without compromising the performance for the functionality.

Throughout the years, technological innovations have turned mini excavators from simple machines to very sophisticated equipment. The first versions had minimal controls and were limited in use, but the current models are equipped with advanced hydraulics, electronic control panels, and even GPS. These upgrades have greatly increased the quality of the work that can be done, as well as the safety and comfort of the operator.

In the 1990s and early 2000s, the use of mini excavators became very popular in Europe and North America. The idea of using smaller machines for construction and development projects was soon embraced by contractors and developers for its dual economic and operational advantages.

Several companies, such as Bobcat, Caterpillar, Kubota, and Komatsu, started to come up with bright ideas that stirred the interest of both small business owners and corporate clients.

Today, there are many different reasons for having a particular mini excavator, and the designs of these machines are even more diverse. The emergence of eco-friendly electric models marks a new era of zero-emission performances that are suitable for indoor and environmentally sensitive spots. Moreover, we expect the mini excavators to be even more efficient, easier to use, and convertible with the advancements in technology.

Benefits of Using a Mini Excavator

Versatility and Adaptability

One of the most special things about a mini excavator is its amazing versatility. Basically, these machines manage to perform many functions at once. The list of tasks on a construction site that the machine can do without any problem includes digging trenches and foundations, removing debris, and even lifting materials. These machines, due to their small size and ability to make sharp turns, can be used not only in the interior but also in narrow outdoor areas where there is limited space—street construction and small-scale landscaping are examples of such works.

When it comes to working with various attachments, small excavators can do wonders. What used to take several hours to change a digging bucket into a hydraulic breaker or an auger can now be done within a few minutes. In addition, this feature to simply change out the tools for one to complete the work of many has significantly lowered the amount of machinery required in one place.

Moreover, a mini excavator can be extremely helpful in different sectors, which include but are not limited to the following:

- Construction—The use of these beautiful machines to excavate the foundation of the building, to cut very long trenches for electric or water lines, and to prepare the place of the building has gained acceptance in the construction business.

- Landscaping—The landscaping activities were already complicated; however, with machines, things have become easier as it is with digging ponds, uprooting stumps, and leveling terrain.

- Agriculture—It is through technology that we have been able to achieve the installation of fences, the digging of irrigation channels, and the handling of manure to be quicker and easier tasks than what they used to be.

- Demolition—Besides only tearing small parts of buildings, mini excavators also can be employed to help in the process of demolishing by breaking the concrete.

Not only that static, but also this trait of the mini excavators can bring huge benefits to the workers because it will lessen the downtime. First and foremost, there is no doubt about the importance of mini excavators in both residential and commercial developments; thus, they are exceptionally rewarded with their value time and again.

Cost-Effective Operations

Mini excavators offer most of the things large ones can do at way less cost and are generally more economical in terms of purchase and running costs. Usually, their smaller engines mean better fuel economy, and their lighter-weight design means tires and tracks are less likely to have issues; therefore, the maintenance needs are also lower.

Besides, they need less space and infrastructure for their operation; as a result, a minimum of money is spent on job site preparation. Their transport, by which they are very easy, eliminates the necessity of specialized trailers or hauling permits, and thus the logistics expenses are considerably lowered. This in turn seems to be quite convenient for small contractors or businesses that are working with very tight margins.

Moreover, the rental prices of mini excavators are quite reasonable, and this is advantageous for those who only require them for a limited period. Additionally, it is needless to mention that the easy operability of such machines clears the path for the fast and smooth pre-operation briefings or training, and anybody who is somewhat familiar with basic techniques will be able to grasp the controls in a couple of minutes.

On the side of the owners, the conservation practices, like strict adherence to using the lowest fuel-consuming engine types and scheduled maintenance, and as a result, the users’ repeat obligation to treat such a brand as their favorite one, turn into long-run money savings. In this way, mini excavators are pioneers in equipment that is agile and yet economical in business operations that seek great efficiency.

Mini excavators are of different types, and one main distinction is between tail swing and zero tail swing ones. When you have even just basic knowledge about machines, you will realize that the absolute characteristics and most practical applications of two types of mini excavators are very different.

While the small machines of the tail swing type feature a balancing weight that juts out beyond the track’s width, the zero-tail-swing variants don’t have that at all. This traditional design allows for better stability and, thus, higher lifting capacity. As a result, these types are especially ideal to be used in vast and open spaces without worrying about run-ins with other things. However, one should not forget that the rear part of these types can be extremely dangerous while in cramped spaces, as it could knock into walls, trees, or buildings as it is rotating, given that it is the most common place to hit during the process.

Contrarily, the compact designs of the zero tail swing mini excavators do not have rear overhang, and the house of the machine can be easily rotated within the width of the tracks. These are the most suitable types for job sites with limited space or in the city areas. This feature not only gives easy and quick access to hard-to-reach spots but also decreases the chance of getting hurt or damaged. While they can never be quite as good at the heavy lifting of their tail counterparts, the compromise is often valued greatly in tight quarters.

Picking one of these types from the other mainly depends on the nature of your work. For the most part, if you are working in large open areas, then the tail swing will be a good option for you to take advantage of the performance perks. However, if you are constrained in a narrow alley or working indoors, then regardless of your skills, zero tail swing will bring operational efficiency and a sense of security to you.

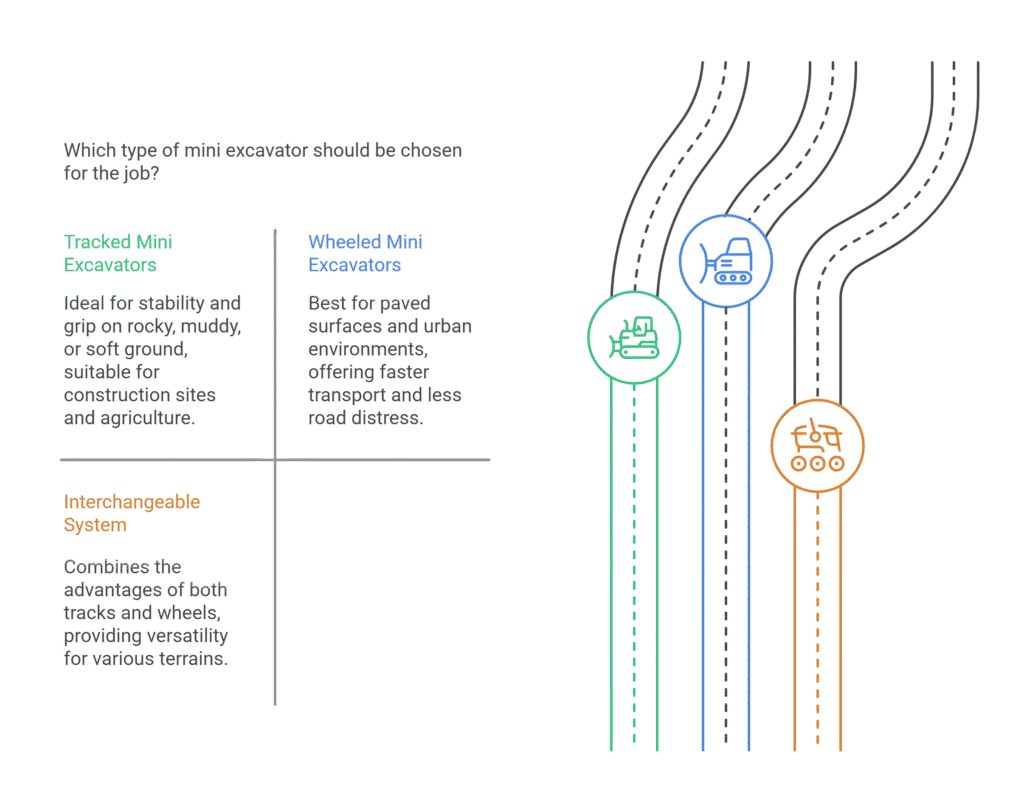

Wheeled vs Tracked Mini Excavators

Landscaping and Construction

Mini excavators are nothing but a dream come true for the landscape industry. The combination of their tiny footprint, flexibility, and the ability to operate several attachments simultaneously makes them irreplaceable in both residential and commercial landscaping projects. Landscaping will be done more efficiently and powerfully with the use of a mini excavator no matter if it is reshaping the land, digging garden beds, installing water features, or even planting trees.

In construction, the benefits of mini excavators are even more diverse. Does the job call for digging a trench for plumbing or the electrical works?

Mini excavators are capable of making clean and accurate cuts. Are you building a foundation for a small structure or just a bit more home? Without a doubt, they can excavate the required space efficiently, and at the same time, there will be no damage to the nearby structures or hardscaping. Their ability to break and lift with accuracy reduces the number of people needed to do the job, shortens the deadlines, and keeps the projects under the assigned budget.

The mini excavators are excellent in the following cases as well:

- Backfilling and grading: After plumbing or foundation work, they do a very nice job of the area so that it is leveled and smooth enough for further service.

- Installing drainage systems: Their precise and barely noticeable maneuvers are just perfect for working around the underground utilities.

- Breaking concrete and asphalt: Besides that, with the suitable attachments, the machines are also able to perform demolition work.

Moreover, due to their great versatility, mini excavators will be spotted working on anything from the lushest of residential gardens to the most extravagant commercial developments and even school campuses. They have a small size but a big effect.

Demolition and Utility Work

Demolition is hardly just about the application of brute force—it is, however, also about control. To achieve both brute force and control, mini excavators play a crucial role. They are the ones that are perfectly suitable for small-scale demo projects while failing to be able to bring down skyscrapers.

A garage, a shed, some interior walls, a patio, a sidewalk, and a deck—these are all things that are within the range of mini excavators. As a result, it is with attachments such as hydraulic hammers, rippers, and grapples that mini excavators can materially dismantle and extract the material efficiently while at the same time, they are not damaging the surrounding environment.

Mini excavators are the basics of utility work. In addition, they represent the best machines that are the most suitable for trenching and pipe laying.

What about the digging of a channel for a new sewer line or a safe electrical conduit? It could be done by so small heavy equipment without much effort, and at the same time, the surface disruption would be minimized around the area. With the use of GPS and laser-guided attachments, contractors can conduct very accurate digs that can comply with city and state codes.

The few and very specific utility works that are the reasons for the excellent performance of mini excavators are as follows:

- Water line installation and repair

- Gas pipe trenching

- Electrical cable routing

- Fiber optic conduit placement

- Stormwater management systems

Due to their ability to move fast, they are also the first choice in emergency utility repairs. Thanks to their size, they can get into narrow, small areas that are not accessible to other larger machines. The main point? For critical infrastructure and controlled demolition, mini excavators are among the most trusted tools in the field.

Hydraulic System and Attachments

The mini hydraulic system is the very core and the life of any mini excavator. Basically, it serves as the power source for the arm, boom, bucket, and any attachments that a user requires. The basis of the mini excavator’s versatility is being able to be equipped with a strong and durable hydraulic system. Tech-minded basic hydraulics will allow you to run various demanding attachments like mulchers or trenchers.

One of the criteria for choosing a mini excavator is to check the GPM (gallons per minute) and PSI (pounds per square inch) ratings of the hydraulic system installed on it. The higher the flow and pressure, the stronger and more capable the machine will be. In addition, make sure that the unit is equipped with hydraulic couplers and lines that are easy for quick changes in the attachments to be carried out.

Talking about attachments, the mini excavator is the best choice. With the support of a well-constructed mini excavator, you can expect it to be compatible with many kinds of attachments, such as:

- Standard and heavy-duty buckets

- Hydraulic breakers

- Augers

- Thumbs (mechanical and hydraulic)

- Rippers and grapples

- Trenchers

- Plate compactors

Before, it was difficult to do a job that required multiple machines. Today, many modern models come with hydraulic quick couplers which, at the push of a button, you can switch to another attachment. Thus, this simple feature can make you save time and money.

Cabin Comfort and Controls

The operator of the cab is the “brain center” of the entire machine. A good cab can boost your work and prevent stress. Check the models that have a perfect seat, easy-to-understand control layouts, and good visibility. Top-quality suspension seats, adjustable armrests, and air conditioning make a long day more comfortable.

Often, mini-excavators have these features:

- LCD or touch screen for diagnostics and monitoring

- Joystick for smoother and more accurate operation

- Heated and air-conditioned cabins for year-round comfort

- 360-degree visibility, sometimes with rear cameras

The ease of use is a big factor for the less-experienced operators; a user-friendly control system can greatly speed up the process of getting to work. In many machines, there are also control pattern options (e.g., ISO or SAE) so that the operator can select the one he/she finds most familiar.

A quiet, sealed cab can definitely cut down on operator fatigue and still keep the particles, noise, and bad weather away from the operator. Thinking about the amount of time you or your workers will be in that area, it is a great idea to get a machine with a comfortable and well-equipped cab, which will be a great return on both productivity and morale the next time.

Assessing Your Job Requirements

Actually, the first and most vital point before buying or renting is to assess the job requirements you have. In different sizes, various outputs, and even with feature differences, the mini-excavator is versatile; therefore, the first step is to figure out what you want to use them for.

Start by answering these questions one by one:

- What kind of terrain will you be working on? Muddy, rocky, flat, or paved?

- How deep does the digging have to be? Different mini-excavators have different maximum digging depths which range from 5 to 14 feet.

- What is the necessary lifting capacity? In case you will be lifting the pipes, debris, or heavy materials, then make sure that the machine is capable of doing it.

- How much room is there on the site? If your workplace has tight corners or narrow access points you will need a compact, zero-tail-swing model to get there.

Moreover, think about how often you use the machine. If it is only for a few hours during the week, renting might be more economical. However, if it is a daily workhorse, then why not get a high-quality model with a long-lasting support warranty which might cost you a little more but will definitely be worth it.

Understanding Size and Weight Classifications

In general, the mini excavators are between 1 and 10 tons in weight. The smallest models (1-3 tons) are for indoor or backyard work, whereas the heaviest (5-10 tons) offer more digging power and depth for larger projects.

Here’s a quick breakdown:

- 1–2 ton class: Perfect for simple yardwork and residential projects.

- 3–5 ton class: The best of both worlds with a suitable size and power for common contractors.

- 6–10 ton class: Nice for the most demanding jobs but still with good mobility.

Most of the time, big machines are loaded with various features such as better tracks, advanced hydraulic systems, and more luxurious cabin space. Nevertheless, they also require more transport planning and could produce more surface disturbance—so having balance is important.

H2: Top Mini Excavator Brands and Models to Consider

Popular Manufacturers in the Market

For the part of trustworthiness and top performance, the following few names practically always are at the very front of the line in the mini excavator market: They help you have the confidence to choose a product from a famous brand because it delivers good customer support, you can get spare parts easily, and it also has good resale value.

Think about these top names that you shouldn’t fail to consider:

- Bobcat: Popular for its resistance to wear, user-friendliness, and success with the numerous dealers worldwide. The E35 and E50 are great user-friendly models.

- Caterpillar (CAT): Gives high-end possibilities and the highest durability. They are accompanied by the CAT 301.8 and CAT 305 CR highly rated models.

- Kubota: A longtime favorite for its low fuel consumption and reasonable price. The company’s KX and U series (KX040-4, U35) are its bestsellers.

- Takeuchi: One of the earliest compact machine makers, with rugged performance with the TB216 and TB240.

- Komatsu: The most amazing and comfortable features are made possible by advanced technology. Some of their models that come to mind first are the PC30MR and PC55MR.

The key to the best model is matching the specific demands of your job while still fitting within your budget and comfort expectations. Always try a unit or take it for a test run before you decide to buy it.

Daily Maintenance Suggestions

If you want your mini-excavator to keep performing at its best for a long time, then you have to take good care of it. Just like with a car, the life of the machine can be greatly extended with regular inspections and routine servicing.

Some basic maintenance is:

- Daily Inspections: Before every use, check fluid levels, tire or track condition, hydraulic lines, and bucket teeth.

- Change Oil and Filters: Follow the manufacturer’s recommended intervals for engine oil, hydraulic fluid, and fuel filters.

- Clean the Undercarriage: Mud, rocks, and debris are a constant threat to your tracks and the components of the undercarriage. Make sure to clean it after every job.

- Check the Battery: Make sure, in particular, during winter that the terminals are clean and the battery is holding a charge.

- Lubricate Moving Parts: Apply grease to all the pivot points, joints, and moving arms to lower the friction between parts.

Log all your service work in a logbook and always use original equipment manufacturer parts. What is a leaking hose or a dirty air filter for a small issue that can lead to a large problem if it is ignored?

Common Issues and Troubleshooting

The best machines are not perfect, and sometimes they have issues. Here are some common problems and their causes:

- Slow or jerky operation: Could be caused by low hydraulic fluid or clogged filters.

- Difficulty starting: The battery, fuel lines, and glow plugs in cold weather are the things to check.

- Strange noises from the undercarriage: Most of the time it is the symptom of worn track rollers and loose bolts.

- Overheating: A clogged radiator or low coolant levels are the reasons that may cause it.

The majority of contemporary mini excavators feature onboard diagnostics that notify you about problems at an early stage. Never pay no attention to warning lights or alarms. If in doubt, seek the assistance of a certified technician before using the machine again.

Preventive maintenance is your best friend when it comes to keeping repair costs low and maximizing uptime.

Pre-Operational Checks

It is very important to check the safety and readiness of the machine before it is even started. It is easy in the world of machines to skip pre-operational checks, which may result in accidents, equipment damage, or costly delays.

Following is the checklist that should be used on every occasion:

- Inspect hydraulic hoses for leaks or cracks

- Make sure that fluid levels (engine oil, hydraulic oil, coolant) are at the required level

- Check the tracks or tires for damage or excessive wear

- Be sure that the bucket and attachments have been properly secured

- Test all lights, horns, and safety indicators

- Clean windows and mirrors for clear visibility

It only takes a few minutes to complete these inspections, but they can save you a lot of time—or even lives—in the future.

On-Site Safety Practices

Once you are at the place of work, it is absolutely necessary to keep up with the safe operating practices. Some of the rules that must be followed are given below:

- Use safety gear: Hard hats, gloves, boots, and high-visibility vests are essential.

- Get 360-degree awareness: Before swinging the arm or moving, always check your surroundings.

- Seat belts are to be used: they keep you secure and reduce injury during unexpected movements.

- Do not work at edges or on unstable ground: mini excavators are light and can easily tip over.

- The bucket should not be overloaded: In such a case, the machine can tip, or the hydraulics can get damaged.

- Communicate clearly: Radios and hand signals are ideal when working with a team.

Even if the task is a little bit boring, still, take your time. Nothing should be more important than the safety of the worker, even the speed of the work. Along with regular safety drills, training will definitely keep a person’s skill sharp and also offer the comfort of being ready for an emergency.

When It Is Appropriate to Rent

Most of the time, the best option for businesses or individuals who only need the machine for short periods or occasional projects would be to rent a mini excavator. It is possible to get access to the latest models and technologies through renting without necessarily having to make the huge purchase deal. Furthermore, it is a good idea if you want to select various sizes or brands before coming up with a machine that will fit your long-term requirements.

These are some of the cases where renting is a better option:

- Projects with a very short duration: Assuming that the work will be done within the next two weeks, it will be more reasonable to rent the required equipment.

- Use that is not frequent: For instance, a small contractor or a landscaper that only calls for an excavator four times a year might be such a case.

- Renting helps if there are budget problems: By avoiding a large capital expenditure, rent helps to keep up the good cash flow.

- There is limited space for storage: there is no issue that you will be faced with long-term storage or maintenance.

- Servicing is a part of the rental agreement: most of the rental agreements have a provision for basic servicing that gives you the liberty to concentrate on the job.

Lots of rental companies have different rental packages, such as daily, weekly, or monthly, to accommodate clients according to their budgets and timelines. On the other hand, if you are a frequent renter, then it may become very expensive in the long run.

Benefits of Owning Your Own Machine

Mini excavator ownership literally translates into a lot of wonderful benefits in the long run. In fact, this can be very handy for companies that heavily rely on such a machine on a daily basis. Sure, the process of buying a machine is a huge exercise, but on the other hand, the repeated rental rates can be quite substantial, and a machine on the premises can make ownership more cost-effective over a period of time; that’s for sure.

Major benefits of ownership are

- Availability: The machine is at your disposal 24 hours a day, 7 days a week without that unexpected rental and waiting times, and so on.

- Customization: Just for enhancements and commodities use that are fitted perfectly to your requirements.

- Asset value: A mini-excavator that was bought puts more value in your company in contrast to machine equipment that is only rented.

- Lower long-term costs: Once the machine is fully paid, the only spending that is left is maintenance and fuel.

- Tax deductions: Practically, most localities give the businesses the chance of deducting the equipment purchases made.

Meanwhile, owning a vehicle entails certain obligations such as accident, maintenance, and insurance. But for many experts, and especially those with constant work, the decision to have a mini-excavator is a wise one and a strategic step forward in their careers.

Initial Investment Costs

The acquisition of a mini excavator is not a standard sale; in essence, the costs can be diversified to a great extent depending mostly on size, brand, features, and condition. Here is what you might get on average:

- New Mini Excavators: $25,000 – $90,000+

- Used Mini Excavators: $15,000–$50,000

- Compact Models (1–2 tons): $25,000–$35,000

- Mid-Size (3–5 tons): $35,000–$60,000

- Heavy Mini Excavators (6–10 tons): $60,000–$90,000+

Just remember that the equipment, like an air-conditioned cabin, GPS, advanced hydraulic system, and quick coupler can be significantly higher in price. Warranty packages and dealer support may also affect the total investment.

Moreover, you will also need to take into consideration:

- Delivery and transport costs

- Insurance

- Financing charges (if applicable)

- Initial attachments (buckets, thumbs, augers)

To properly budget means to look beyond the price tag. Knowing your needs and seeing if you plan to use the mini excavator long-term will help you decide whether to go for a brand-new unit or a certified pre-owned one.

Ongoing Maintenance and Operational Expenses

The moment you are a mini-excavator owner the real cost of ownership follows. Luckily, these small machines are pretty cheap in terms of operational costs if we compare them to full-size ones, but it is still important to budget for maintenance.

The monthly operational expenses can be:

- Fuel: $100–$300, depending on usage and fuel prices

- Regular maintenance: $200–$500/month (includes fluids, filters, greasing)

- Tires/tracks replacement: Every 1,000–2,000 hours, costing $1,000–$2,500

- Repairs and parts: Budget $500–$1,000 annually for unforeseen issues

- Insurance and registration: $500–$1,500/year

On top of that, a storage space is necessary to keep the machine safe from weather and vandalism. In case you do not own a garage or shed, then a securely rented yard or container might be the solution for you.

Mini excavator divided budget planning for both short- and long-term will guarantee that your machine gives a return of value without the risk of draining your finances unexpectedly.

Electric and Hybrid Models

Considering the environment being the focus of the whole world, electric and hybrid mini excavators are becoming more and more popular. They are very advantageous to use inside the building, within the city, or in areas affected by the environment. Volvo, Bobcat, and JCB are already among the first brands to bring out electric battery-powered models that cause zero emissions and make low noise.

Some of the advantages of the electric mini excavator program are:

- Very low noise level—it is a place of use, such as a hospital, a school, or a residential area with neighbors.

- Non-polluting—Demolition of a building or work underground is done, and then it is suitable for that place.

- Operating fuel and maintenance costs will be reduced—by using fewer parts that wear and tear and parts without oil changes.

- Environmentally friendly—It can help in meeting the standards and regulations regarding eco-friendly buildings.

There are still some problems, namely short battery life, a high initial cost of the product, and the area of charging. Nevertheless, as the battery technology gets better, it will be easier and faster to trail these obstacles and thus have more eco-friendly and efficient job sites.

Smart Controls and Automation

Even small excavators are not excluded from the impact of automation. Manufacturers greatly enhance the accuracy, safety, and ease of use of the smart technologies they implement. Many new models have adopted GPS, laser-guided controls, and telematics as their standard features.

Emerging tech features include:

- Remote operation—Control your excavator from a distance, thus allowing safety in the area of hazardous zones.

- Auto-grade systems – Make sure of accurate slopes and trench depths with the least amount of operator input.

- Integrated diagnostics—alerts along with reminders for maintenance come through mobile apps.

- With joystick customization, you can control input and personalize settings to adapt your workflow.

Besides, these smart systems reduce the learning curve for new operators and thus increase productivity for the seasoned ones. When more jobsites go digital, the technical business keeps the upper hand in the competition to stay ahead of the tech.

Conclusion

Mini excavators have turned from a mere option into a must-have for modern construction, landscaping, and utility works. Their small size, multifunctional abilities, and user-friendliness are what make them the perfect team for both professional contractors and day-off fighters.

If you want to use one for a few hours during a hurried job or if you are planning to take advantage of a long-term project, being well aware of their types, application, and maintenance will definitely make you win more than what you invest.

The future of digging is compact, smart, and incredibly efficient electric models, which are the latest besides the traditional diesel beasts. Whatever your need is, there will always be a mini excavator designed for you to do the task—faster, safer, and with less hassle.