Typhon Mini Excavator with Premium-Class Attachments

The Typhon Mini Excavator is a very flexible piece of equipment, which is widely used in different fields, such as building, gardening, and farming.

The compact excavator can, however, only provide its full performance if the right attachments are used. The usage of effective attachments does not only make work smooth; it also turns the machine into something quite engaging.

As tools, these attachments are of primary importance in human life as they enlarge the view of the excavator and the time available for the task due to their efficient performance.

In this respect, they may spruce up the productivity of the operator and, hence, extend the limits of his working skills. For instance, the hydraulic thumb attachment can make the primary digging machine a very good tool for the job of lifting and transferring heavy materials; in other words, the work that can now be accomplished is widened.

Furthermore, the significance of high-quality attachments is not confined to functionality only, for they also act as a crucial part of the safety and reliability aspects during operation. Substandard parts can cause machine malfunctions, which could pose a serious security risk for the operator and, consequently, lead to downtime and repair costs.

Durable attachments designed for harsh work environments are not only able to withstand the conditions; they can also operate efficiently and consistently over a long period. Time is crucial for your business, and falling behind schedule can result in significant financial losses.

Therefore, procuring quality accessories for your Typhon Mini Excavator is not only a way to boost performance; it is also crucial for protecting your investment and ensuring that your workflow operates at maximum efficiency.

Quality attachments are important not only in increasing the performance but also the versatility of your Typhon Mini Excavator.

If you want to upgrade your mini excavator with the best attachments, you will ensure not only getting the increased performance but also cost savings and higher productivity.

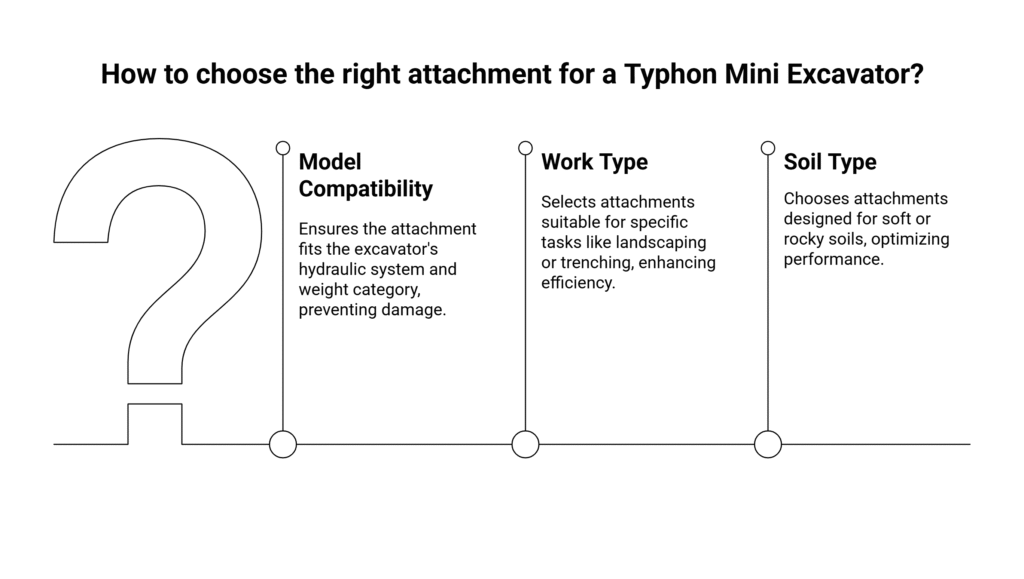

When selecting accessories for your Typhon Mini Excavator, you should think about compatibility, durability, and versatility as major factors.

Indeed, there are a lot of kinds of attachments for Typhon Mini Excavators, and they can be anything from buckets, hammers, to augers, perfect for different activities.

For the effectivity and safety of the attachments of your Typhon Mini Excavator, correct installation as well as compatibility are crucial.

The Benefits of Upgrading Your Typhon Mini Excavator with High-Quality Attachments

Upgrading your Typhon Mini Excavator with first-rate components will not only provide immediate performance improvements but also a plethora of other benefits.

The most important advantage of these is the increase in machine’s productivity and flexibility. The right attachments will allow your mini excavator to carry out many different jobs such as digging, grading, carving, etc.,

Correspondingly, the dirt bucket can be a good option for leveling the ground very exactly, while a hydraulic breaker can ease the breaking of a building apart. Therefore, the multitasking effect reduces the need for numerous machines, hence lowering costs. In addition to productivity, effective tools also play a crucial role in efficiency.

These parts are needed to be compatible with the machine; thus, your task is to choose the accessories best suited for this. On the one hand, it can shorten the time required to complete the work, but on the other hand, it also allows the operator to perform the tasks with less physical effort.

At the same time, the attachments with high-quality performance usually come with different kinds of advanced systems like quick couplers or a hydraulic system giving the user the convenience of merely changing of one switch to another, and at the same time, the time taken to change can be very less.

From this, a good result is seen in that the cost of the project is lower because of the reduced numbers of human working hours plus they work at a very fast rate.)

Factors That Will Impact Your Choice of Attachments for Your Typhon Mini Excavator

Attachments available for Typhon Mini Excavators vary in number and use, and they can be used in a broad range of applications. Among the various categories of available attachments, digging buckets are one of the most popular and are used in most industries.

Attachments available for Typhon Mini Excavators vary in number and use, and they can be used in a broad range of applications. Among the various categories of available attachments, digging buckets are one of the most popular and are used in most industries.

It is important to have such a wide variety of buckets, because then they can have varied capabilities and, consequently, will be used for different tasks and can be suitable for different situations.

The general kind of buckets is most common, as they are used in a normal measurement of a digging activity, but the special categories like small trenching or spading buckets are employed in respective applications.

The narrowest bucket, they called it the trenching bucket, which is the one to be used right now when the space one is digging is quite confined; hence, it is high up the list of things to be done. It’s hard to imagine an excavator without a bunch of other auxiliary stuff, like the hydraulic thumbs, the auger, and the grapple, which are also part of a backhoe machine.

A hydraulic thumb is a good replacement for human fingers, strong in grip, as it provides additional strength in handling rather than what fingers can do.

An auger, apart from controlling the earth’s moisture, can also be used to drill holes of different sizes (from small to large) on the earth’s surface, making them suitable for tree planting and carrying out water and drainage projects. The machine’s job is made a million times easier with grapples, which do not do anything on the site except transport things from one end to the other.

How to Ensure Proper Installation and Compatibility of Attachments with Your Typhon Mini Excavator

For the Typhon Mini Excavator, make sure of two things: attaching the equipment properly and the right compatibility of attachments. The initial thing to do is to follow the manufacturer’s advice on fitting the attachments to your equipment and the exact procedures to follow.

Hopefully, Typhon gives a lot of paperwork where, among other things, it clearly states for each model the list of the suitable attachments along with the specifications and surely any of the necessary adapters or couplers for installing them.

This step-by-step approach will make it easier for you to avoid problems with the wrong kind of assembly of the attachments or the loss of their functionality. The choice of the attachment should be just the first stage of the procedure.

The next steps include a series of checks before the actual process of attaching starts. It is necessary to look for any signs of cracks or scratches on both areas, i.e., the attachment and the excavator that are making the connection.

These irregularities, if any, should raise a red flag, as they may result in a safety breach during the operational process. When you are hosting the attachment, be 100% certain that all bolts and pins are in place and that locks are secure as per the manufacturer’s rules.

If you feel that something is slackened, do inspect the link of the accessories now and then, as this will help you to confirm its stability during repetitive stress. The benefit of the proper fitting is not just in the good performance but also the long life which the attachments and the excavator together enjoy.

Extreme Versatility Delivered in a Matter of Seconds

Dynamic Reaction to the Challenge of Different Job Needs

Quick switching between various attachments is a time-saving ability that enables workers to match the ever-changing job needs smoothly without experiencing a lot of downtime.

As an illustration, when the task of a project is altered from excavation to grading, having a quick coupler system installed allows the easy transition of a digging bucket to a grading bucket instantaneously in a few minutes.

Improving Efficiency Using Specialized Attachments

The use of special equipment can boost efficiencies considerably on the job site. To give an example, one can quickly break and remove the concrete or asphalt surfaces with a hydraulic breaker attachment much faster than otherwise it would have been done, the conventional method being the slower one. This feature, besides speeding the execution of projects, also cuts down on labor expenditures of manual demolition activities.

Speeding Up Jobs With Auger Devices

Moreover, adoption of an auger attachment can speed up works like post-hole digging or foundation preparation by allowing operators to drill multiple holes efficiently with no need of more equipment.

Do’s And Don’ts for Your Typhon Mini Excavator Attachments

It is very important to take good care of your Typhon Mini Excavator attachments in order to ensure they are long-lasting and always in good condition.

Regular checks should be conducted regularly to be aware of any faults or problems that may change the expected performance. This ranges from looking at the hoses for any signs of leakage, testing the pins, and the bushings for wear, and lubricating the moving parts.

If the small problems are repaired immediately, it can avoid more serious problems and thereby save money and time. By cleaning the tools after they are used, you are prolonging the lifespan and the efficiency of the equipment. Dirt, debris, and other corrosive materials might cling to the equipment during operation, thus causing corrosion or rust in the end.

By simply cleaning them once in a while, you maintain their functionality and purity. Furthermore, if the tools are stored in a cool and dry place when not in use, it will protect it from any external damages that could cause destruction.

When workers follow these maintenance protocols, they will not only prolong the time before replacement but also ensure the equipment will always be prepared to be operational.

Where to Get the Most Durable Attachments for Your Typhon Mini Excavator

The process of selecting the most durable attachments for your Typhon Mini Excavator is a job that requires the point-to-point identification of suppliers and manufacturers of great repute and those who have stood out in product quality.

One method would be to consult the list of authorized dealers, who are the people to approach if you want the Typhon equipment; these dealers are well-stocked with all the authentic attachments that are tailor-made for use with the Typhon series.

Purchasing via an authorized dealer’s channel guarantees that customers receive only the best products that not only conform to the manufacturer’s specifications but also are covered by warranties or given guarantees.

Another approach you can use is to find the reputable online marketplaces that concentrate on the construction accessories and the parts of the machinery.

UsConstruction equipment websites usually have user reviews and comments, which help assess the quality and performance of the products from the perspective of other operators.

However, it is important to be sure that the sellers are trustworthy before making any transactions through the internet; you can do a background check on the sellers who have a good reputation among their previous clients.

Furthermore, attending industry-related exhibitions or trade fairs is a surefire way to network with manufacturers and suppliers and test their products in person, thus making an informed decision before the purchase.

It is by considering the above pointers that you can easily source attachments for your Typhon Mini Excavator without any hitches, thus influencing your decision positively when you are looking to upgrade your machine’s equipment to be of excellent quality and capability to fit into your needs without any difficulty.